Prioritizing heat safety & codes serves as the primary defense against structural fires and catastrophic liability claims in modern residential and commercial fireplace installations. Choosing the wrong stone or ignoring localized heat zones leads to sudden thermal shock, resulting in structural failure or expensive legal non-compliance. Builders and contractors face significant financial setbacks when inspections fail because of improper clearance or material choices that cannot withstand the intense heat output of high-efficiency gas or wood-burning units.

This technical overview provides a standard operating procedure for selecting and installing stone surfaces that meet stringent safety standards. We examine the performance differences between natural and faux stacked stone, the mechanics of thermal expansion, and the critical 12-inch clearance rule for combustibles. The guide also addresses the role of high-temperature adhesives in preventing delamination and provides specific strategies for managing heat zones around firebox surrounds to ensure long-term durability and code approval.

Is All Stacked Stone Heat Safe? Natural vs. Faux Performance

Metamorphic stones like quartzite and slate provide the highest thermal stability for fireplace surrounds, while sedimentary stones and faux alternatives risk calcination or pigment degradation under sustained high temperatures.

Thermal Stability of Natural Quartzite and Slate Panels

الحجر الطبيعي varieties such as quartzite and slate maintain structural integrity under high temperatures, making them ideal for fireplace surrounds. Our 2026 collection utilizes 100% real quarried stone which is inherently non-combustible. These materials demonstrate high thermal shock resistance and remain stable even at sustained temperatures reaching 300°F. Because these panels consist of raw minerals, they do not release volatile organic compounds (VOCs) or toxic fumes when exposed to heat, a critical safety factor for indoor air quality.

| Material Category | Thermal Performance | استقرار اللون |

|---|---|---|

| Natural Quartzite/Slate | High; Stable up to 300°F+ | Permanent (Mineral-based) |

| Manufactured (Faux) Stone | Moderate; Risk of backing warp | Low; Pigments fade over time |

| Sedimentary (Limestone) | Sensitive; Prone to calcination | Stable but texture may degrade |

Heat Sensitivity in Manufactured and Faux Stone Backing

Manufactured stone performance depends heavily on the chemical composition of the binders and the specific backing systems used. Faux stone often uses concrete composites and surface pigments that may fade or degrade when placed too close to a heat source. Testing in 2026 indicates that lower-quality manufactured panels can warp due to thermal stress, which eventually leads to panel detachment or delamination. Because of these vulnerabilities, manufactured products usually require greater clearance distances than الحجر الطبيعي to prevent unsightly discoloration.

Material Degradation and Calcination in Sedimentary Stones

Limestone and other sedimentary stones react differently to extreme heat compared to metamorphic stones. Limestone specifically faces increased porosity and potential calcination when exposed to extreme, direct heat for prolonged periods. This chemical reaction can weaken the stone’s structural density. Metamorphic stones like the quartzite and slate found in our “10 كبيرة” inventory generally outperform sedimentary options in high-heat residential applications. While all الحجر الطبيعي is non-combustible, the structural density dictates how well the material handles rapid temperature shifts without fracturing.

Long-Term Aesthetics and Color Retention Under Heat

The visual longevity of a fireplace feature depends on how the stone’s color is produced. حجر طبيعي مكدس retains its color permanently because the hues are mineral-based rather than added surface pigments. Many manufactured stone products utilize iron oxide pigments that can shift in tone or “yellow” after repeated heating and cooling cycles. We recommend applying a high-quality, heat-rated natural stone sealer to protect the surface from soot and smoke staining, ensuring the architectural finish remains pristine over decades of use.

فهم “Clearance to Combustibles”: The 12-Inch Rule

Adherence to the 12-inch clearance rule ensures that thermal radiation from the firebox does not trigger pyrolysis in wooden architectural elements.

Defining the 12-Inch Mantel Clearance Standard

National fire safety standards typically require at least 12 inches of clearance between the top of the fireplace opening and the bottom of a combustible mantel. This distance serves as a critical buffer zone where only non-combustible materials, like الحجر الطبيعي مكدسة, should exist. Building codes in 2026 specify that for every inch a mantel projects from the wall, additional clearance height may be necessary to prevent a heat trap. For example, a mantel protruding 6 inches often requires 18 inches of vertical clearance to satisfy the projection-to-height ratio used by modern inspectors.

| Clearance Component | Standard Requirement | Material Compliance |

|---|---|---|

| Vertical Mantel Clearance | 12″ Minimum (Base) | الحجر الطبيعي / Quartzite |

| Horizontal Side Clearance | 6″ to 8″ Sides | Interlocking Z-Panels |

| Substrate Material | Non-Combustible Zone | Cement Backer Board Only |

حجر طبيعي مكدس serves as a non-combustible facing that bridges the gap between the heat source and flammable architectural elements. By utilizing 100% natural minerals like quartzite or slate, installers provide a thermal shield that maintains its structural integrity even during peak fireplace operation.

NFPA-211 and International Residential Code Compliance

Safety protocols for 2026 rely on established benchmarks from the NFPA-211 and the International Residential Code (IRC) to mitigate fire risks. Current IRC guidelines mandate specific separation distances to ensure that surface temperatures of combustible components do not exceed safe limits. When installers neglect these distances, they risk pyrolysis—the chemical decomposition of wood caused by long-term heat exposure—which can lower the ignition temperature of wood framing over time.

- Inspectors verify clearances to ensure wood temperatures remain below the 90°C threshold.

- Professional installers use these codes to determine the exact transition point from الحجر الطبيعي to wood trim.

- Compliance requires measuring from the inner edge of the firebox, not the decorative facade.

Substrate Requirements and Heat Barrier Integration

بينما الألواح الحجرية الطبيعية are non-combustible, the materials behind them dictate the overall safety of the fireplace assembly. Installers must replace standard gypsum drywall with cement backer boards or masonry units within the immediate heat zone. Adhering الحجر الطبيعي directly to combustible studs without a thermal barrier violates most 2026 safety protocols and voids manufacturer warranties.

The use of air-cooled barrier systems allows for reduced clearances in tight architectural designs. These systems circulate air behind the stone facing, significantly lowering the transfer of heat to the interior wall structure. This engineering approach enables modern, flush-mount fireplace aesthetics without compromising the structural integrity of the home.

Vertical and Horizontal Clearance Specifications

Clearance rules apply to both vertical surfaces above the firebox and horizontal surfaces flanking the sides of the opening. Side wall clearances generally require 6 to 8 inches of non-combustible material before wood paneling or cabinetry can begin. Natural stone panels provide a seamless solution for these zones, especially when using Z-shaped interlocking designs that eliminate visible grout lines.

Contractors must measure from the inner edge of the firebox to ensure accurate code compliance. Using CNC diamond-blade precision panels ensures that these safety-critical dimensions are covered with consistent stone thickness, preventing “النقاط الساخنة” where thinner stone might allow higher heat transfer to the substrate.

Premium Stacked Stone for Architectural Needs

Why Thermal Expansion Leads to Cracking in Low-Quality Stone

Thermal stress represents the primary cause of stone failure in fireplace applications, occurring when incompatible material densities or rigid bonding agents cannot accommodate natural expansion cycles.

Materials used in high-heat environments must manage significant internal pressure as temperatures fluctuate. Low-quality or composite stones often contain inconsistent mineral densities that react unevenly to heat sources, leading to structural instability over time.

Mineral Composition and Differential Expansion

The internal structure of the stone determines how it handles heat. When a material lacks a uniform mineral matrix, different parts of the stone expand at different rates, creating internal tension that the material cannot sustain.

- Varying expansion coefficients within a single low-grade stone create internal tensile stress when temperatures rise.

- الحجر الطبيعي with poor grain boundary structures lacks the elasticity to absorb these thermal shifts without fracturing.

- Faux or cultured المنتجات الحجرية using pigment-heavy concrete composites often expand at different rates than their internal reinforcements, leading to surface spiderwebbing.

Adhesive Brittleness and Panel Delamination

The bonding system is just as critical as the stone itself. Failure often begins at the point of contact between the stone and the substrate when the adhesive cannot withstand thermal cycling.

- Inferior resins and glues often lose their grip and become brittle when exposed to the 2026 industry standard heat tests.

- We use high-strength, stone-specific epoxy adhesives designed to maintain a permanent bond even as the stone naturally moves.

- A lack of flexible bonding in cheap panels means the stone has nowhere to expand, so it either cracks or detaches from the substrate.

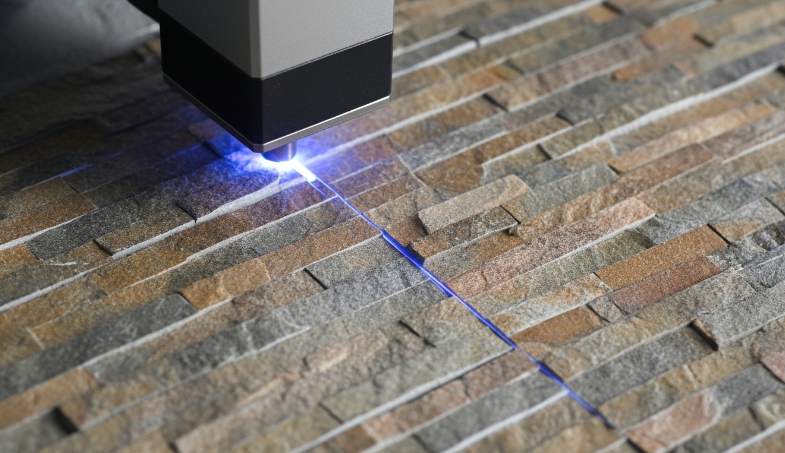

Precision Cutting to Prevent Pressure Build-up

Mechanical pressure between individual stones can accelerate damage if the installation is too tight or the cuts are imprecise. Manufacturing defects create “pinch points” that concentrate heat and stress in small areas.

- Inconsistently sized stones in low-quality panels leave no room for natural movement, forcing stones to press against each other until they snap.

- We utilize advanced infrared cutting equipment to ensure every component fits with microscopic precision, allowing for uniform heat distribution.

- Poorly manufactured panels often skip the critical three-stage quality check, allowing stones with pre-existing micro-fissures to reach the job site.

Firebox Surrounds: Managing High-Temperature Zones Safely

Architectural firebox surrounds require a transition from standard combustible framing to a strictly non-combustible stone barrier to prevent structural ignition and manage the 300°F thermal loads common in modern heating appliances.

Material Integrity: Natural Stone as a Non-Combustible Barrier

طبيعي الألواح الحجرية serve as a critical safety barrier because they are inherently fire-resistant. Unlike manufactured or faux stone products, 100% natural minerals do not release toxic fumes or undergo chemical off-gassing when exposed to sustained heat. Selecting quarried materials ensures the surround functions as a heat shield rather than a liability.

- Specify 100% quarried slate, quartzite, or marble to ensure the surround acts as a functional heat shield without structural degradation.

- Verify that الألواح الحجرية meet non-combustible classification standards required by 2026 residential and commercial fire codes.

- Avoid pigment-heavy faux stone products to eliminate the risk of melting or toxic off-gassing in high-heat zones.

Regulatory Compliance for Gas and Solid Fuel Fireplaces

Current 2026 safety standards require a nuanced approach to heat management based on the specific fuel source. Modern gas appliances now operate under strict glass temperature regulations, while traditional solid fuel units demand significant clearance to prevent the ignition of nearby wood framing. Compliance requires adhering to specific material thicknesses and established separation distances.

- Adhere to the 172°F glass temperature limit regulations now standard for modern gas appliance installations.

- Distinguish between the clearance requirements of factory-built units and traditional masonry fireplaces during the design phase.

- Apply the 12-inch rule for combustibles if the underlying wall structure contains wood framing, regardless of the القشرة الحجرية thickness.

Substrate Preparation: Cement Board and Thermal Support

The longevity of a مدفأة حجرية مكدسة depends entirely on the substrate. The intense thermal cycling—the constant expansion and contraction of materials—can cause standard drywall to crumble or adhesives to fail. Using cement-based backer boards and specialized adhesives creates a stable foundation that resists delamination and cracking.

- Replace standard gypsum drywall with cement-based backer boards in all zones designated as high-temperature contact areas.

- Utilize high-strength, heat-rated epoxy adhesives to secure the 8-13 lbs/sqft panels, ensuring the bond remains stable during thermal cycling.

- Install matching L-shaped corner pieces to manage thermal expansion at joints and maintain a seamless architectural profile.

How Professional Adhesives Prevent Stone Delamination from Heat

The longevity of a تركيب حجر مكدس near heat sources depends less on the stone itself and more on the chemical integrity of the adhesive bond under repetitive thermal cycling.

Modern ألواح حجرية مكدسة utilize specialized epoxy resins engineered to create a permanent bond between the natural stone and the substrate base. Adhesives specifically formulated for الحجر الطبيعي provide chemical stability that prevents the stone from separating when surface temperatures rise. Manufacturing processes in 2026 focus on high-tensile strength resins that maintain their grip even during prolonged exposure to fireplace heat. This chemical composition resists the softening or “off-gassing” common in lower-grade glues used in budget القشرة الحجرية, ensuring the structural assembly remains intact regardless of the fireplace’s BTU output.

Accommodating Thermal Expansion and Contraction

Professional-grade adhesives act as a flexible interface that absorbs the physical movement of stone as it heats and cools. الحجر الطبيعي expands when heated; elastomeric adhesive compounds allow for this micro-movement without breaking the bond. Advanced polymers maintain performance across extreme temperature ranges, typically from -40°C to +90°C, ensuring integrity in both indoor and outdoor settings. Using adhesives with high elasticity prevents the brittle fractures that lead to stone pieces falling off the panel over time.

| مقياس الأداء | Factory-Applied Epoxy Resin | Standard Field Mortar |

|---|---|---|

| Temperature Stability | -40°C to +90°C (Stable) | Degrades above 50°C |

| Expansion Management | Elastomeric (Flexible) | Rigid (Prone to Cracking) |

| Heat Retention Strength | >95% Bond Strength | Rapid Loss of Adhesion |

| Chemical Off-Gassing | Zero VOC / Heat Stable | Potential Odor Release |

Factory-Controlled Bonding vs. Site Application

The bond strength of a pre-assembled لوحة الحجر المكدسة depends heavily on the environment where the adhesive was applied. Applying adhesives under controlled temperature and pressure conditions ensures a more uniform and secure bond than manual on-site application. High-quality manufacturers utilize three-stage inspection protocols to verify adhesive coverage before the panels leave the facility, drastically reducing the risk of delamination once the stone faces heat. Automated application systems eliminate human error, ensuring every square inch of the stone surface receives the precise amount of resin required for heat resistance.

- Precision diamond-blade CNC edges ensure a tight fit, minimizing the gap where heat can penetrate the adhesive layer.

- Factory environments maintain optimal humidity levels (40–95°F) for curing, which is impossible to guarantee on a construction site.

- Multi-layered composite backings absorb thermal stress, redistributing heat across the panel to prevent hotspots.

Long-Term Durability in High-Heat Zones

Professional adhesives must withstand thousands of heating cycles near fireboxes and ovens without losing structural integrity. Testing shows that high-quality stone adhesives maintain over 95% of their bond strength after repeated exposure to radiant heat. Properly bonded panels function as a single unit, preventing moisture from entering the adhesive layer and causing steam-related pressure pops. Contractors prioritize factory-assembled panels to avoid the common failures seen when using standard thin-set mortars for heavy natural stone pieces, especially in high-traffic commercial zones or residential focal points.

خاتمة

Selecting الحجر الطبيعي مكدسة and adhering to strict clearance codes mitigates fire risks while preventing structural issues like cracking or delamination. Architects and inspectors rely on these established safety standards to ensure the structural integrity of high-heat fireplace surrounds. Precision material sourcing and correct adhesive application eliminate the common hazards associated with thermal expansion.

Review the Top Source Stone technical data manual or explore the Big 10 inventory to find project-ready natural stone solutions that meet international building codes. Contact us to request a professional sample for your next commercial or residential specification.

الأسئلة المتداولة

Is stacked stone heat safe for high-efficiency gas fireplaces?

نعم، الحجر الطبيعي مكدسة materials such as quartzite and slate are exceptionally heat-safe, maintaining their structural integrity at sustained temperatures of 300°F and higher. For high-efficiency gas fireplaces, which generate significant radiant heat, it is critical to use natural stone or manufactured panels that have undergone rigorous ASTM thermal testing to ensure they can handle the specific thermal output of the unit.

What is the minimum clearance for a wood mantel over stone?

Industry standard safety codes generally require a minimum clearance of 12 inches between the top of the fireplace opening and the bottom of a combustible wood mantel. However, this clearance often increases based on the depth of the mantel; a common rule of thumb is to add one inch of vertical clearance for every inch the mantel protrudes from the stone face beyond a standard depth.

Can stacked stone crack from excessive fireplace heat?

While high-quality natural stone is resilient, cracking can occur due to thermal shock or calcination, particularly in softer stones like limestone. To prevent cracking, it is essential to use a heat-rated thin-set mortar or adhesive that allows for the natural expansion and contraction of the stone during heating and cooling cycles.

Does the stone need a special fire-rated sealer?

Standard stacked stone does not require a “fire-rated” sealer, but it does require a heat-resistant, penetrating sealer (such as a silane/siloxane blend). You must avoid topical or film-forming sealers, as these can yellow, bubble, or release fumes when exposed to the high temperatures of a fireplace surround.

How to protect the stone from direct flame contact?

Stacked stone is designed for use as a decorative surround and should never come into direct contact with flames. Protection is achieved by ensuring the stone is installed only on the exterior facade, while the interior of the fireplace is lined with professional-grade firebrick or a manufacturer-approved steel heat shield to contain the direct combustion zone.