Adhering to Fireplace Special Specs serves as the primary safeguard against structural fires and the legal liabilities associated with non-compliant masonry work. While standard stone veneers might look identical to heat-rated alternatives, the physics of thermal transfer means that using the wrong materials leads to bonding failure or combustion of the wall studs behind the stone. Contractors who bypass specific heat-resistance protocols risk failed inspections and rework that erodes profit margins.

Questo guide functions as a technical standard for installing stone over existing brick or metal surrounds while maintaining strict clearance-to-combustibles codes. We analyze the necessity of high-flex adhesives to handle constant thermal cycling and provide the requirements for mounting heavy displays on uneven stone surfaces. Every section focuses on finishing rough edges and the safety reasons why a hearth remains a mandatory component of floor-to-ceiling designs.

Why Fireplaces Demand a Different Class of Stone Installation?

Installing stone on a fireplace is a specialized engineering task where thermal dynamics dictate material performance more than aesthetics.

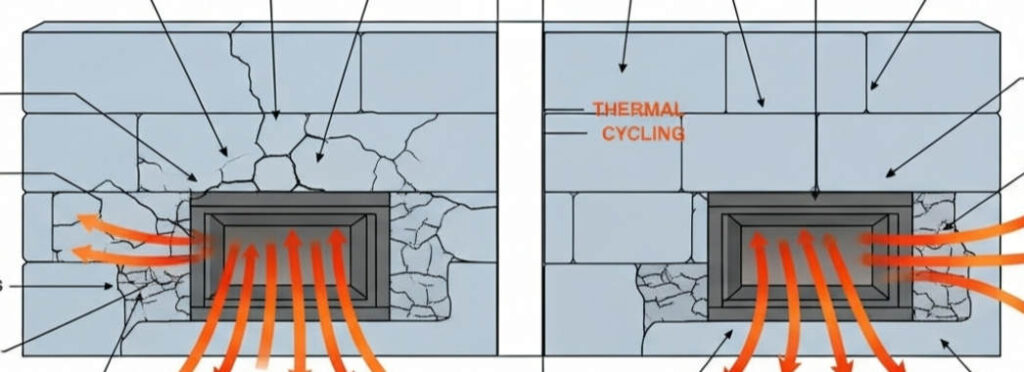

Standard rivestimento delle pareti techniques fail when applied to fireplace surrounds because they ignore the physical realities of thermal cycling. A fireplace is a high-heat engine that forces building materials to expand and contract rapidly. If the installation does not account for these movements, the mechanical bond between the stone and the substrate will eventually shear, leading to delamination or cracked panels.

Managing Thermal Expansion and Contraction

Fireplace surrounds experience significant temperature swings that cause building materials to expand and contract at different rates. Pannelli in pietra naturale maintain structural integrity under these heat cycles far better than manufactured composites or “falso” stones, which often contain resins that degrade or off-gas when heated.

- Thermal cycling puts constant stress on the bond between the stone and the substrate, requiring materials that can absorb minor shifts.

- Pietra naturale inherently resists the warping associated with 2026-standard high-efficiency heating units.

- We recommend specialized backing systems, such as reinforced cement board, to prevent the stone from shifting or cracking over time.

Adhesive Requirements for High-Heat Environments

Standard mortars and thin-sets often become brittle and fail under the intense heat of a firebox. For a permanent bond, installers must transition to high-performance bonding agents. We prioritize high-strength epoxy resin adhesives specifically formulated to withstand elevated temperatures without losing grip.

Safety standards in 2026 require a minimum shear bond strength of 50 lbs per square inch. This ensures the stone remains anchored even as the underlying wall heats up. Furthermore, heat-resistant curing practices are essential; firing up the fireplace too soon after installation can cause the adhesive to become brittle, leading to premature failure.

Substrate Preparation and Load Bearing

Mentre natural stacked stone is designed for efficiency, the high-heat context requires a more robust foundation than a standard drywall project. Pannelli in pietra naturale weighing between 8-13 lbs per square foot require a substrate that won’t flex when the chimney heats up.

- Install cement board or metal lath over existing surfaces to provide a heat-stable foundation that prevents moisture-related bond failure.

- Proper surface cleaning is non-negotiable; soot, dust, or old paint will compromise the mechanical bond of the stone.

- Using a scratch coat over masonry surfaces creates the necessary “key” for the adhesive to lock into.

Non-Combustible Material Standards

Using 100% Pietra naturale provides a significant safety advantage by meeting strict fire codes for fireplace surrounds. Unlike artificial “colto” pietre, genuine stacked stone from Top Source Stone won’t fade or discolor from UV exposure or heat. Natural quarried stone is inherently non-combustible and does not emit toxic fumes when exposed to high heat.

Our interlocking Z-shape panel system provides an additional layer of protection. This precision CNC-cut design eliminates visible grout lines that could otherwise become points of heat penetration or soot accumulation. By utilizing a male-female connection system, the installation effectively camouflages the substrate, providing a seamless architectural finish that is as safe as it is visually striking.

Is Your Surround Safe? Meeting Clearance-to-Combustibles Codes

Fireplace cladding safety hinges on understanding the specific heat dissipation profiles of the underlying firebox, as site-built masonry and factory-engineered units operate under entirely different regulatory mandates.

Distinguishing Between Masonry and Factory-Built Requirements

Building codes in 2026 categorize fireplaces into two distinct groups, each with unique clearance mandates. National standards differentiate between site-built masonry units and pre-engineered factory systems. Masonry fireplaces typically require 2 to 4 inches of clearance from all framing components to prevent heat transfer to the home’s structure. Contractors must verify the fireplace type before installing stacked stone to ensure the substrate meets local fire safety protocols. While Pietra naturale itself is non-combustible, the materials behind it—such as wood studs or plywood—remain vulnerable to pyrolysis if clearance gaps are ignored.

| Fireplace Category | Standard Clearance | Primary Regulation |

|---|---|---|

| Site-Built Masonry | 2″ a 4″ from Framing | NFPA 211 / Local Code |

| Factory-Built (Pre-Fab) | 0″ a 1″ (Unit Specific) | UL 127 Listing |

| Combustible Mantels | 6″ to 12″ Vertical Gap | IRC / CSA Standards |

Standard Clearances for Wood Framing and Combustible Trim

Safety codes prevent heat transfer to the structural skeleton of the home through specific spacing rules. Combustible materials must remain at least 6 to 12 inches away from the firebox opening, depending on the projection depth of the finish material. Trim may abut masonry surfaces only if the stone or brick thickness exceeds 12 inches at the point of contact. Professionals should utilize these guidelines to avoid structural fires caused by long-term heat exposure:

- Maintain a 1/8-inch per inch of projection rule for mantels and trim.

- Install stone over non-combustible cement board rather than gypsum to provide a superior thermal barrier.

- Use metal lath and a scratch coat when transitioning from masonry to framed walls to ensure bond integrity.

Compliance with UL 127 Surface Temperature Standards

Factory-built fireplaces undergo rigorous testing to determine how close combustible walls can sit to the unit. Systems tested to UL 127 standards must maintain exterior surface temperatures below 175°F above ambient air. Installers should check the manufacturer’s data plate for specific “zero-clearance” ratings before finishing the wall with pannelli di pietra impilati. Pietra naturale functions as a heat sink, but it does not permit the reduction of mandated air gaps behind the wall assembly. Forgetting this technicality can lead to trapped heat that compromises the fireplace’s venting efficiency or structural stability.

Calculating Mantel Height and Projection Limits

Mantels act as heat traps, requiring precise vertical placement to avoid ignition risks. Codes restrict how far a mantel can project from the wall based on its height above the firebox. Deep mantels require higher mounting points to allow heat to dissipate naturally into the room. While using rivestimento in pietra naturale across the entire facade helps protect the wall, the mantel itself remains subject to clearance-to-combustible rules. Using an infrared temperature gun during the first few fires allows installers to verify that the calcolo face and mantel remain within safe operating temperatures.

Durable, Fast-Installing Natural Stone Ledger Panels

How to Handle Stone Installation Over Existing Metal or Brick Surrounds?

Directly bonding natural stone to legacy substrates requires neutralizing existing contaminants and establishing a mechanical profile to prevent delamination during thermal cycling.

Surface Preparation for Masonry and Brick Substrates

Transforming an outdated brick fireplace requires removing all contaminants to ensure the new stone panels achieve a permanent mechanical bond. Soot, wax, and creosote act as bond-breakers; we clean these surfaces using a wire brush and a pH-neutral degreaser before proceeding. If the brick is painted, the mortar will not bond to the surface. We use a grinder to scuff or score the paint, exposing the porous masonry underneath.

Once the surface is clean and profiled, apply a concrete bonding agent or a thin scratch coat of polymer-modified thin-set. This step levels the uneven brick faces and provides a consistent substrate for our interlocking Z-panels. Allowing this layer to cure for 24 to 48 hours prevents the brick from pulling moisture out of the final adhesive layer too quickly.

| Tipo di substrato | Primary Preparation Method | Recommended Bonding Agent |

|---|---|---|

| Porous/Bare Brick | Wire brush cleaning & degreasing | Polymer-Modified Thin-set |

| Painted Masonry | Mechanical grinding to expose 90% brick | High-bond Concrete Agent |

| Metal Surround | 80-grit sanding & solvent wipe | Two-Part Heat-Rated Epoxy |

Adhesion Strategies for Smooth Metal Surrounds

Metal surrounds expand and contract at significantly different rates than Pietra naturale. This thermal movement requires specialized adhesives that maintain flexibility under heat. Standard mortars often fail on non-porous metal surfaces, leading to stone delamination. We use high-strength epoxy adhesives or specialized modified mortars designed specifically for metal-to-stone applications.

Preparation involves sanding the metal surface with 80-grit sandpaper to create a physical profile. This allows the adhesive to grip the surround mechanically rather than relying solely on chemical suction. Before installation, confirm the metal frame is structurally capable of supporting the 8-13 lbs per square foot weight of natural stone panels without sagging or pulling away from the wall framing.

Integrating Cement Backer Boards for Structural Stability

For projects where the original surface is too damaged, uneven, or heavily painted, installing a new substrate provides the most reliable foundation. Fasten 1/2-inch cement backer boards over the existing surround. Use masonry anchors for brick or self-tapping screws for metal framing, ensuring the board is plumb and flat.

- Seal all backer board seams with alkali-resistant fiberglass mesh tape and thin-set to create a unified, rigid plane.

- Utilize the new flat surface to perfectly align 6” x 24” pannelli in pietra, ensuring seamless transitions across the fireplace face.

- Use matching pre-fabricated L-corners to wrap the fireplace returns, maintaining texture consistency.

Code Compliance and Thermal Safety Standards

Installation must adhere to updated 2026 safety regulations regarding non-combustible materials and firebox clearances. Verify that the stone thickness does not obstruct the operation of air intake vents or glass doors on zero-clearance metal fireplaces. Obstructing these vents can cause the unit to overheat, potentially damaging the internal components or the surrounding wall structure.

Maintain required distances between the firebox opening and any surrounding combustible materials as dictated by local building codes. Seal the transition between the stone edge and the firebox with high-temperature silicone or fire-rated caulk. This prevents heat bypass into the wall cavity and ensures the entire installation meets current UL 127 standards for factory-built systems.

Thermal Cycling: Why Only High-Flex Adhesives Should Be Used?

Thermal cycling creates mechanical shear stress at the bond line; high-flex adhesives serve as a kinetic buffer that prevents pannelli in pietra naturale from delaminating during rapid temperature fluctuations.

Managing Differential Thermal Expansion Rates

Pietra naturale and cementitious backing substrates possess different Coefficients of Thermal Expansion (CTE). When a fireplace reaches operating temperature, the pietra e muro expand at conflicting rates and speeds. Rigid, traditional mortars lack the elasticity to accommodate this mismatch, which results in internal shear stress. This pressure eventually forces the stone to “pop” or causes the entire panel to warp as the materials struggle to move independently.

| Adhesive Class | Thermal Flexibility | Primary Failure Risk |

|---|---|---|

| Type S Mortar | Low (Rigid) | Brittle cracking under rapid heat |

| Polymer-Modified Thin-set | Moderare | Bond fatigue over 5+ years |

| Modified Epoxy Resins | High (Elastic) | Minimal / Negligible |

Modern high-flex adhesives act as a decouple layer that absorbs the kinetic energy generated by CTE mismatch. By allowing for micro-movements without breaking the bond, these adhesives ensure that 100% natural minerals—whether slate or quartzite—remain structurally integrated with the substrate regardless of the heat intensity. Rigid adhesives fail 2026 thermal shock tests because they cannot deform enough to accommodate this substrate movement.

Preserving Bond Integrity Across Temperature Extremes

Adhesives must maintain a stable glass transition temperature to remain effective. In high-efficiency gas fireplaces or outdoor installations, the bonding agent faces both freezing ambient temperatures and intense localized heat. Modern modified epoxies provide the necessary elasticity without sacrificing the high-strength grip required for heavy, 13-pound-per-square-foot panels. Standard mortars often suffer from embrittlement when subjected to these repeated cycles, losing their adhesive properties over time.

The chemical composition of these advanced adhesives ensures they do not soften or lose adhesion when temperatures rise near the firebox opening. These formulations resist the degradation common in lower-grade materials, ensuring that the stone facade retains its architectural integrity even under direct UV exposure or high salinity in coastal regions.

Preventing Delamination in High-Stress Applications

Delamination represents the primary cause of failure in installazioni di caminetti in pietra. It is rarely a failure of the stone itself but rather a failure of the bond line due to long-term thermal fatigue. Architects and professional installers now favor silicones or modified epoxies that prioritize thermal shock resistance to meet 2026 building standards. These resins ensure a permanent bond between the stone veneer and the panel substrate, even under constant environmental pressure.

Advanced application-driven strategies focus on long-term durability. By selecting adhesives that can withstand the rigors of thermal cycling, we eliminate the risk of stones falling or joints opening. This engineering-first approach protects the investment in premium nature-cut materials, guaranteeing that the aesthetic finish remains flawless for the life of the structure.

Can You Safely Drill and Mount a Heavy TV Over a Stone Fireplace?

Securing a 2026-standard large-format display over natural stone requires a direct mechanical connection to the home’s structural framing, as the stone veneer is an aesthetic facade and cannot support external shear loads.

Structural Stud Alignment and Weight Distribution

Safe installation dictates that all mounting hardware must bypass the pannelli in pietra and anchor directly into the structural studs. Pietra naturale impilata from Top Source Stone typically weighs between 8 to 13 lbs/sqft, which already puts a constant load on the wall substrate. Adding the weight of a heavy TV and an articulating mount creates a leverage point that can cause stone delamination or wall failure if you only anchor into the stone or cement board.

- We use deep-scan stud finders to locate wood or metal framing behind the pannelli in pietra before we begin any drilling.

- Lag bolts must penetrate at least 2.5 inches into the structural studs to safely support the cantilevered weight of modern displays.

- The wall frame carries the entire load of the electronics; the stone surface serves only as a decorative bypass layer.

Drilling Precision for Natural Stone Panels

Natural materials like quartzite and slate possess high density, so they require specific tools to prevent cracking. Using a standard hammer drill on a high-vibration setting can easily shatter the interlocking panels or break the high-strength epoxy bond holding the ledgestone strips together. Precision is key to maintaining the visual integrity of the CNC diamond-blade edges we provide.

- Use diamond-tipped masonry bits to create clean pilot holes without applying heavy pressure that might crack the stone.

- Maintain a low drill speed to manage heat buildup, which preserves the structural integrity of the stone’s internal composition.

- Drill through the center of a stone piece rather than at the seam between Z-shape panels to minimize the risk of edge chipping.

Heat Mitigation and Pull-Down Mount Integration

Fireplaces generate significant convective heat that rises directly into the TV’s internal components. While the Pietra naturale acts as a heat sink, it can also radiate that heat back toward the display. Integrating the right mounting hardware is just as important as the stone selection for long-term electronics protection.

- Pull-down or articulating mounts allow the TV to sit further away from the stone face, which improves airflow and reduces heat soak.

- A mantel or a protruding stone shelf serves as a vital heat shield to deflect hot air away from the screen.

- Check the fireplace manufacturer’s clearance-to-combustibles even when using non-combustible stone, as the TV itself is a combustible component.

Hardware Selection for Irregular Stone Surfaces

The varied depths of our “Ruvido” O “Premium” stone series create an uneven mounting surface that can bend a TV bracket if it is cinched down tight. Since our panels vary from 0.75” to 1.75” in thickness, you cannot simply flush-mount a flat bracket without preparation.

- Heavy-duty spacers or extra-wide washers compensate for thickness variations to create a perfectly level mounting plane.

- Solid masonry anchors provide a secondary securement point if the mount footprint is wider than the available wall studs.

- Inject a small amount of silicone into the pilot hole before inserting the bolt to seal the stone and prevent dust migration behind the panels.

How to Finish the Rough Stone Edge Around the Firebox Opening?

Precision finishing at the firebox transition prevents substrate exposure and manages thermal expansion, ensuring the Pietra naturale facade maintains structural integrity during high-heat operation.

L-Shaped Corner Pieces for Seamless Interior Returns

Exposing the raw, cut edges of a stone panel at the firebox opening signals a low-quality installation. To achieve a professional return, we utilize pre-fabricated L-shaped corner pieces. These components wrap the natural stone texture from the face of the wall into the interior of the firebox opening, concealing the cement board or metal lath substrate entirely. This approach provides the appearance of a full-bed depth masonry hearth without the associated weight or cost.

- Install matching L-shaped pieces to wrap the stone from the face of the wall into the firebox return.

- Ensure the stone sits flush against the metal firebox flange to create a professional, integrated look.

- Utilize the 90-degree factory edge to maintain a consistent 2026 design standard for clean masonry lines.

Metal Trim Profiles for Contemporary Fireplace Borders

Modern architectural designs often shift away from traditional masonry edges in favor of industrial accents. Metal trim profiles—specifically L-channels or square-edge trims—provide a crisp, linear transition between the irregular surface of the pietra accatastata and the smooth firebox frame. This method is particularly effective for protecting the edges of pannelli contabili from physical impact while framing the firebox as a focal point.

- Select an L-channel or square-edge trim that matches the thickness of the pannello in pietra, typically between 0.75 and 1.5 inches.

- Secure the trim to the cement board before applying the stone to create a protective “frame” for the ledger panels.

- Choose matte black or brushed finishes to complement the natural quartzite or slate textures found in the Rough Series.

Infrared Precision Mitering for Custom Edge Alignment

When dealing with non-standard return depths or custom fireplace geometries, off-the-shelf corners may not fit the project requirements. In these instances, installers use wet saws equipped with infrared guides to create 45-degree mitered edges on-site. This technique allows for a monolithic appearance where two stone panels meet at a corner, creating a continuous vein pattern that wraps around the firebox edge with surgical precision.

- Use wet saws with infrared guides to ensure perfectly straight diagonal cuts across the interlocking stone sections.

- Apply high-strength epoxy resin in a matching color to bond the mitered pieces together permanently.

- Back-fill any minor gaps with color-matched stone dust and adhesive for a monolithic appearance.

Applying High-Heat Sealants to Exposed Transitions

The junction where the stone meets the metal firebox is a high-stress zone subject to constant thermal cycling. Using standard grout or mortar in this gap is a mistake; the different expansion rates of metal and masonry will inevitably cause the mortar to crack and fall out. A dedicated thermal-safe barrier is required to maintain the aesthetic and safety of the fireplace opening over time.

- Apply a bead of black high-temperature silicone between the edge of the stone and the firebox frame to allow for thermal expansion.

- Avoid using standard grout in this transition zone, as thermal cycling causes traditional masonry mortar to crack and drop out.

- Seal the final exposed stone edges with a pH-neutral natural stone sealer to prevent soot buildup and staining.

Why a Hearth is Mandatory for Floor-to-Ceiling Stone Facades?

Full-height stone installations create significant structural and thermal demands that only a dedicated hearth can resolve through load distribution and fire-code compliance.

Meeting 2026 Building Code Compliance

Current safety standards require precise hearth dimensions to mitigate fire risks in both residential and commercial properties. Inspectors look for these non-combustible zones as a prerequisite for approving full-height stone installations. Failure to adhere to these measurements often results in failed inspections and costly retrofits.

- International Residential Code (IRC) standards in 2026 require a hearth extension of at least 16 inches in front of the firebox opening.

- Side extensions must reach at least 8 inches beyond each side of the fireplace opening to catch stray sparks or shifting logs.

- Non-combustible zones must be clearly defined before the stone veneer application begins.

Protecting Combustible Flooring from Thermal Stress

The hearth serves as a critical thermal break between the active heat source and vulnerable floor materials. While natural stone ledger panels possess high heat resistance, the radiant energy they absorb and emit can damage nearby wood, laminate, or carpet over long periods.

- The hearth stops embers or rolling logs from making direct contact with flammable floor coverings.

- Using a stone hearth creates a continuous non-combustible transition from the firebox to the room floor.

- Proper material selection for the hearth ensures the floor substrate remains below critical temperature thresholds during peak firing.

Managing Vertical Load and Structural Weight

Floor-to-ceiling stone facades exert massive downward pressure. Natural stone panels, such as those in the Top Source Stone inventory, weigh between 8 and 13 pounds per square foot. This creates a heavy vertical assembly that needs more than just wall anchors to remain stable over decades.

- A masonry hearth provides a reinforced base that helps distribute the weight of the stone facade across the subfloor.

- Reinforced footings or support columns often sit beneath the hearth to prevent the floor from sagging under the weight of the full-height stone.

- The hearth acts as a starting ledge, ensuring the first row of stone remains perfectly level as the installation climbs toward the ceiling.

Visual Proportions for Tall Stone Features

Beyond structural and safety requirements, the hearth provides the aesthetic anchor necessary for massive stone walls. Without a horizontal base, a floor-to-ceiling stone wall often looks top-heavy or architecturally incomplete.

- The hearth covers the transition where interlocking Z-shape panels meet the floor, effectively hiding expansion gaps.

- Designers use the hearth to define the fireplace as a distinct architectural element within a large room.

- A well-proportioned hearth grounds the vertical lines of the stone, creating a balanced focal point.

Conclusione

Successful fireplace stone installation relies on a balance of safety compliance and high-performance materials. Using the right thermal-rated adhesives and maintaining proper clearances prevents structural failure while protecting overhead electronics from heat damage. These technical standards ensure the finished surround remains a durable, low-maintenance centerpiece for years to come.

For large-scale developments or retail inventory, we provide technical specifications and project-ready solutions for our natural stone collections. Contact our team to request a sample crate or a wholesale quote for our current inventory.

Domande frequenti

Can I install stacked stone over a painted brick fireplace?

Direct installation over paint is not recommended because the bond is only as strong as the paint’s adhesion to the brick. To ensure a professional-grade installation, you must either mechanically strip the paint to expose the porous brick or install a metal lath and a cementitious scratch coat. This provides the reinforced backing and 50 psi shear strength required to support the weight of the stone during thermal cycling.

What is the best heat-rated adhesive for fireplace stone veneer?

The industry standard for stone veneer in high-heat environments is a polymer-modified, thin-set mortar meeting ANSI A118.4 or A118.15 specifications. These specialized adhesives are engineered to handle the thermal expansion and contraction (thermal cycling) of the fireplace without losing bond strength. Always ensure the mortar is rated for a minimum 50 lbs per sq. inch shear to guarantee long-term durability.

Is natural stacked stone safe for high-efficiency gas fireplaces?

Yes, natural stacked stone is inherently non-combustible and is a premium choice for high-efficiency gas fireplaces. Because these units generate significant localized heat, it is critical to use a high-performance mortar and maintain the manufacturer-specified clearances. Properly installed natural stone acts as an excellent thermal mass, safely absorbing and radiating heat back into the room.

How to mount a TV bracket securely on a rugged stone wall?

To secure a TV bracket to uneven stacked stone, you must use a hammer drill with carbide-tipped bits to penetrate the structural substrate behind the veneer. Use heavy-duty masonry sleeve anchors or wedge anchors for maximum weight capacity. To account for the rugged surface, utilize spacers or standoffs between the bracket and the stone to create a perfectly level mounting plane, preventing the bracket from flexing or warping.

How to clean soot stains off stone around the firebox opening?

For effective soot removal, start with a dry soot eraser or a vacuum to remove loose particulates. For deep cleaning, apply a pH-neutral stone cleaner or a paste made of baking soda and clear dish soap. Scrub gently with a soft-bristled brush to lift the carbon stains without etching the stone. Avoid acidic cleaners or harsh chemicals, which can cause permanent discoloration or surface degradation on natural stone materials.