Integrating a hybrid backsplash addresses the escalating maintenance costs and fire safety risks associated with improper stone placement in high-output kitchens. Relying on a single material for the entire wall often forces a trade-off between aesthetic texture and heat-resistant durability. When developers ignore the specific grease-splatter zones or heat-intensity points behind professional ranges, they risk permanent staining or structural cracking that leads to expensive tear-outs and property depreciation.

This guide provides a technical roadmap for executing a zone protection strategy by pairing smooth granite slabs with textured pannelli in pietra. We detail the specific transition methods for granite and stacked stone, explaining how to manage differing material thicknesses and joint sealing. Contractors and designers can use these specifications as a standard operating procedure to maintain visual continuity while meeting the rigorous hygiene and safety standards required for luxury kitchen environments.

Why Traditional One-Material Backsplashes are Becoming Obsolete

Current design standards prioritize dimensional texture and material zoning over the flat, single-material aesthetics that dominated previous decades.

Modern architectural trends favor multi-layered surfaces that create a more engaging living environment compared to flat, uniform tile grids. Standard backsplashes often lack the character required for high-end residential or commercial kitchens, leading designers to integrate materials that offer significant depth. By shifting toward multi-textured environments, developers can create spaces that feel dynamic rather than static.

Shift Toward Visual Depth and Three-Dimensional Texture

Flat, single-material backsplashes often fail to provide the architectural weight needed in premium kitchen environments. In 2026, depth has become the primary driver of luxury aesthetics. Pannelli di pietra impilati solve this by introducing natural shadows and highlights that change throughout the day based on kitchen lighting, making the wall itself an evolving design element.

- Pannelli di pietra impilati introduce organic shadows and highlights that react to shifting kitchen lighting.

- Homeowners increasingly select textured stone to break up the monotony of smooth cabinetry and countertops.

- Dimensional surfaces provide a high-impact focal point that defines the character of the room without needing additional decor.

Strategic Zoning for Performance and Aesthetics

Hybrid installations allow for targeted material use, placing easy-to-clean surfaces exactly where they are needed while using decorative stone for broader impact. This performance-based zoning ensures the kitchen remains functional for heavy cooking while maintaining a high-end visual appeal. We see professional designers reserving smooth slabs for high-splatter zones behind the range while utilizing pannelli contabili for expansive accent walls.

- Smooth slabs provide a hygiene-focused solution for areas directly behind the stove or sink.

- Mixed-material strategies offer the rugged beauty of natural stone without compromising maintenance in cooking zones.

- Using different materials helps define specific functional zones within open-concept kitchen and dining layouts.

Natural Stone Authenticity vs. Synthetic Uniformity

The move away from mass-produced, identical tiles reflects a growing preference for the unique variations found in real quarried stone. The market has largely rejected the “perfect” uniformity of synthetic materials in favor of the authentic color shifts and textures that only 100% natural minerals can provide. These natural variations ensure that every installation is a unique custom feature.

- Each natural stone panel offers unique textures and color variations that artificial options cannot replicate.

- Vero pannelli contabili in pietra increase property value by providing a premium, custom-built appearance.

- Interlocking stone systems eliminate visible grout lines, offering a more seamless and sophisticated look than traditional tile grids.

IL “Zone Protection” Strategy: Smooth Slab behind the Range vs. Stone Accents

Modern kitchen architecture requires a dual-material approach that isolates high-heat cooking zones with wipe-clean surfaces while utilizing the organic texture of natural stone for surrounding architectural depth.

Functional Slab Placement for High-Splash Zones

Positioning smooth, non-porous slabs directly behind the cooking range addresses the mechanical demands of professional-grade kitchens. These surfaces withstand intense heat and constant grease accumulation that would otherwise penetrate porous materials. By selecting a matching granite or quartzite slab from our quarry sources, designers maintain visual continuity with the countertops while providing a shield that protects the wall substrate from thermal fluctuations.

| Zone Requirement | Selezione dei materiali | Core Performance Factor |

|---|---|---|

| Direct Heat/Grease (Range) | Smooth Polished Slab | Rapid Wipe-Clean Maintenance |

| Perimeter/Feature Walls | Z-Shape Interlocking Stone | Visual Depth & Texture Shadows |

- Smooth surfaces facilitate the instant removal of oil and food particles compared to multi-faceted stone profiles.

- Precision-cut slabs act as a durable heat-resistant barrier for 2026 high-BTU gas ranges.

- Stone slab integration preserves the monochromatic luxury aesthetic without compromising utility.

Textural Depth through Perimeter Stone Accents

Pannelli di pietra impilati naturali create tactile contrast when applied to perimeter walls away from the primary cooking surface. We utilize the Rough Series for these areas to generate dramatic shadows and organic character. This framing technique adds permanent property value by transforming a standard backsplash into a sophisticated architectural feature.

- The Z-shape interlocking system eliminates visible vertical joints, ensuring a professional, grout-free appearance.

- CNC diamond-blade precision allows for tight-fitting modular pieces that camouflage the installation substrate.

- Natural slate and quartzite options provide inherent UV stability, preventing the fading common in synthetic imitations.

Moisture Protection and Sealing Protocols

Successful hybrid installations depend on proper moisture barriers at the junction of different materials. We recommend applying a high-quality, pH-neutral sealant to the Pietra naturale accents to block ambient kitchen vapors and oils. Sealing the transition seam between the smooth slab and the textured panels prevents liquid infiltration into the wall cavity, maintaining the structural integrity of the cement board.

- Use silicone-based sealants at material transitions to accommodate the different expansion rates of slab and pietra del registro.

- Moisture-proof barriers behind pannelli in pietra are essential in high-humidity zones to protect the underlying substrate.

- Periodic re-sealing of stone accents ensures they remain stain-resistant throughout their service life.

Durability and Cleaning Requirements

Concentrating textured stone in low-impact perimeter zones significantly reduces the overall cleaning burden. This strategy allows the natural material to retain its pristine aesthetic for decades without the need for intensive scrubbing. For stone accents, we recommend soft-brush cleaning with water to maintain the 2026 interior design standard without compromising the epoxy bond of the pannelli in pietra.

- Pietra naturale maintains its color integrity better than pigment-based cast stone alternatives.

- Strategic placement in low-impact areas prevents grease buildup in the deep crevices of split-face panels.

- Standard pH-neutral cleaners protect the stone’s mineral surface from etching and chemical damage.

Premium Stacked Stone for Architectural Projects

Achieving Visual Continuity Between Different Stone Surfaces

Effective hybrid stone design relies on “quiet luxury” principles, where varied textures are unified through shared mineralogy and precision CNC joinery to create a cohesive architectural statement.

Design standards in 2026 prioritize a unified color story over matching materials perfectly. When we pair a smooth countertop slab with a textured wall, the pietra accatastata must echo the secondary mineral tones found within the slab’s veining. This approach creates a gallery-like atmosphere, especially when using monochromatic flows like Arctic White marble slabs paired with matching textured marble panels. Maintaining this visual depth requires technical foresight in material selection and protection.

- Select stacked stone panels that mirror the subtle accent hues of the primary slab to anchor the design.

- Utilize Top Source Stone’s same-batch quarry consistency to ensure hue uniformity across large-scale vertical surfaces.

- Apply pH-neutral, breathable sealants to preserve the natural color depth and prevent uneven aging or yellowing.

Vein Alignment and Texture Transitions

Successful installations manage the visual energy between polished slabs and the multi-dimensional surface of natural ledgestone. We direct the linear movement of stone veins toward the textured wall to expand the perceived space. For projects requiring a cleaner profile, the Flat Series provides a transition that mirrors the sleek lines of quartz or polished granite without losing the organic character of Pietra naturale.

- Align slab veining to flow upward into the interlocking stone panel system, simulating a continuous geological formation.

- Use bookmatching principles for high-visibility zones to eliminate jarring visual breaks.

- Leverage CNC diamond-blade precision edges to ensure a tight, male-female interlock that camouflages vertical joints.

Precision Joinery and Shadow Line Detailing

Technical execution at the meeting point of two stone surfaces defines the quality of a high-end kitchen. We implement mitered edge treatments or matching L-shaped corner pieces to eliminate visible seams where different stone planes converge. Incorporating intentional shadow lines at these junctions accommodates natural building settlement while providing a clean architectural break that looks deliberate rather than accidental.

- Install pre-fabricated 90-degree L-corners to ensure texture and color synchronization at all wall transitions.

- Bond slabs and panels with high-strength, color-matched epoxy resins to create permanent, invisible connections.

- Maintain precise tolerance levels during substrate preparation to prevent thickness differentials from affecting cabinet installation.

How to Transition Between a Granite Slab and Stacked Stone Panels

Successful hybrid stone transitions require precise substrate load-bearing assessments and depth-matching to prevent structural failure or unsightly staggered seams at the meeting point.

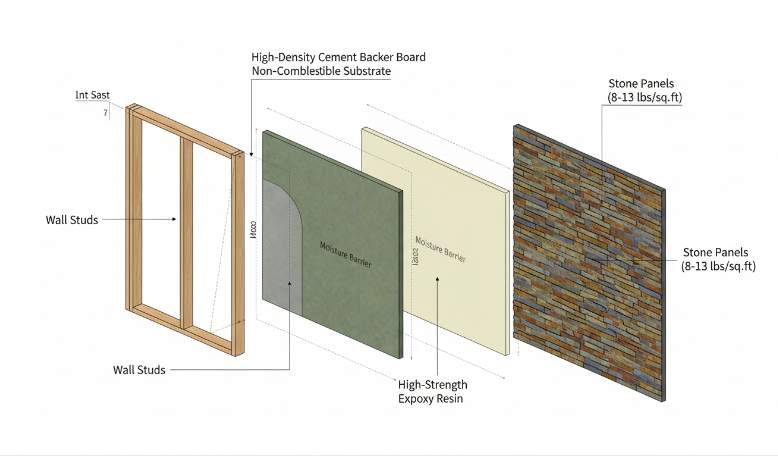

Hybrid backsplash designs are replacing single-material walls in high-end B2B specifications. Combining a solid granite slab behind the range with textured Pietra naturale accents elsewhere offers a balance of easy-clean utility and architectural depth. Achieving this look demands a move away from standard drywall; professional installers must use cement backer board across the entire area to provide a non-combustible, rigid base. This substrate must handle a combined weight where granite often exceeds 15 lbs/sq ft, while our pannelli in pietra naturale impilati range between 8 and 13 lbs/sq ft.

Substrate Preparation and Alignment Protocols

Before any adhesive touches the wall, verify the structural integrity to prevent deflection under heavy stone loads. Use a laser level to establish a primary horizontal transition line where the granite slab meets the first course of pannelli in pietra. This line serves as the anchor for the entire installation. Any deviation here will amplify as you move up the wall, resulting in gaps in the interlocking Z-shape connections.

- Install high-density cement backer board to ensure a uniform surface that resists moisture and heat.

- Calculate the total dead load of the stone to confirm the wall framing meets local building codes for heavy cladding.

- Map out the Z-shape layout to ensure the “maschio-femmina” interlocking system clears the edge of the granite slab without requiring awkward vertical sliver cuts.

Managing Depth and Material Thickness Differentials

Granite slabs and Pietra naturale panels rarely share the same profile thickness. A standard 3cm granite slab (approx. 1.18 inches) often sits flush with our standard stone series but may fall short of the Rough Series. To create a seamless or intentionally tiered transition, you must choose stone profiles that complement the slab’s depth or build out the substrate using additional thinset layers.

| Tipo materiale | Standard Thickness | Weight Profile (Avg) |

|---|---|---|

| Polished Granite Slab (3cm) | ~30 mm | 15 – 18 lbs/sq.ft |

| Standard Stacked Stone (Z-Shape) | 10 mm – 25 mm | 8 – 12 libbre/piedi quadrati |

| Rough Premium Series | Up to 35 mm | ~11.5 lbs/sq.ft |

Selecting the Flat Series (0.75” – 1.25” thickness) provides the easiest path to a flush transition with 3cm granite. If using the Rough Series, which projects further from the wall, consider a “stair-step” transition. This highlights the natural split-face texture of the stone by letting it sit slightly proud of the polished granite surface, creating a shadow line that adds visual interest.

Adhesive Selection and Joint Integration

Varying stone densities require specific bonding agents to handle thermal expansion near ranges. Use polymer-modified thinset mortar for the granite slab to ensure flexibility, and high-strength epoxy resin for the pannelli di pietra impilati to lock them into place. Stagger the panels to prevent vertical seams from aligning with the slab’s edges, which helps the transition feel more organic.

- Back-butter every stone panel to achieve 95% coverage, ensuring no voids exist where moisture could settle.

- Apply a color-matched hybrid sealant or high-quality silicone at the actual meeting point of the two materials to allow for independent movement.

- Avoid using standard grout in the transition joint; silicone better accommodates the different expansion rates of granite and quartzite or slate.

Finishing and Sealing the Transition Zone

The final step protects the porous ledger stone and the polished granite from grease and moisture. Apply a pH-neutral, penetrating sealer to both surfaces only after the adhesive has cured completely—typically 24 to 48 hours. For exposed ends of the backsplash run, utilize matching L-shaped corners from our product line. These pre-fabricated pieces wrap around edges, hiding the cross-section of the granite slab and providing a clean, professional wrap-around finish.

Maintenance in the transition zone requires a soft brush to remove debris from the crevices of the textured stone. Regular sealing—ideally every 12 to 24 months depending on kitchen use—maintains the “Coerenza della cava dello stesso lotto” and prevents oil absorption that could lead to permanent staining.

Case Study: High-End Chef’s Kitchen with Hybrid Stone Design

Modern kitchen architecture in 2026 prioritizes a “zone protection” logic, utilizing high-performance smooth slabs in cooking zones while deploying textured natural stone panels to provide atmospheric depth in social areas.

Integrating Marble Slabs with Linear Pencil Stone

In this luxury renovation, the design team utilized our Pencil Series to create a sophisticated visual hierarchy. The architects specified these linear natural stone panels for the primary accent walls to introduce a dynamic, flowing texture that stands in sharp contrast to the polished countertops. By anchoring the room’s color palette with Pietra naturale, the design influenced the choice of custom cabinetry and high-end appliances, ensuring the textures felt integrated rather than added on.

The project extended this cohesive luxury aesthetic into the butler’s pantry using the Marble Series. This application demonstrates how natural stone selections serve as a unifying thread across different functional zones. By maintaining material consistency from the main prep area to the auxiliary storage spaces, the project achieved a gallery-like atmosphere that defines the current “quiet luxury” market trend.

Zoning the Cooking Space for Protection and Texture

Strategic material placement solved the traditional conflict between aesthetics and maintenance. Designers installed a smooth, non-porous stone slab behind the professional range for immediate cleaning access during high-heat cooking. This functional zone then transitioned into our Rough Series panels for the surrounding backsplash. This hybrid layout balances the professional chef’s requirement for efficiency with the homeowner’s desire for a rustic, tactile environment.

| Installation Metric | Traditional Masonry | Pietra di alto livello Hybrid |

|---|---|---|

| Peso strutturale | 15+ lbs/sq.ft (Requires Reinforcement) | 8-13 lbs/sq.ft (Standard Wall Ready) |

| Velocità di installazione | Hand-Laid (Slow/Labor Intensive) | Interlocking Z-Panels (40% Faster) |

| Corner Execution | On-site Miter Taglio | Pre-fabricated Matching L-Corners |

Streamlining Installation in 2026 Luxury Renovations

The use of lightweight panel systems drastically reduced the project timeline. Because the stone profiles weigh between 8 and 13 lbs/sqft, the installation proceeded on existing wall structures without the need for additional footings or expensive structural reinforcements. Contractors utilized pre-assembled Z-shaped panels and CNC-machined interlocking edges to eliminate visible grout lines, creating a seamless architectural finish that hand-assembled masonry cannot replicate.

- Precision-cut L-shaped corners ensured texture and color synchronization at the kitchen island and structural pillars.

- CNC diamond-blade edges provided tight “maschio-femmina” connections that completely camouflaged the substrate.

- Modular panel delivery allowed the team to meet a tight 2026 delivery schedule by reducing on-site cutting.

Material Consistency and Long-Term Durability Standards

Selecting 100% natural stone ensures that the installation maintains its value through decades of use. Pietra naturale panels resist UV-induced fading, which is a common failure point in synthetic or “falso” alternatives exposed to sunlight through large kitchen windows. To guarantee a permanent bond in the high-heat zones near the cooking stations, we utilized high-strength epoxy resin adhesives that withstand the thermal expansion typical of professional-grade ranges.

Maintenance was addressed through a post-installation pH-neutral sealing treatment. This process simplifies daily cleaning while preserving the non-repeating, organic textures of the Vera pietra. By sourcing from a single quarry vein, the project achieved a 95% hue uniformity across all panels, preventing the patchy appearance often found when mixing materials from disparate batches.

Conclusione

Successful hybrid backsplashes balance the raw texture of Pietra naturale with the practical necessity of smooth, heat-resistant surfaces in high-traffic cooking zones. This design strategy protects the wall from grease and heat while introducing the architectural depth that only genuine ledger la pietra fornisce. Selecting materials sourced from the same quarry vein ensures visual harmony across different finishes and installation methods.

Review our technical catalog to find stacked stone profiles that align with your specific slab requirements. Reach out to our project specialists for material samples or to discuss sourcing for your upcoming design projects.

Domande frequenti

Can I use stacked stone directly behind a professional gas stove?

While visually stunning, installing stacked stone directly behind a high-output professional gas stove is generally discouraged unless it is protected by a high-performance, heat-resistant sealant. The deep crevices and porous nature of ledger stone act as a “grease trap,” making it nearly impossible to clean compared to smooth surfaces. For a professional-grade setup, it is best practice to install a stainless steel or smooth quartz splash guard immediately behind the burners and use the stacked stone for the surrounding accent areas.

How do I match a smooth slab with textured ledger stone?

Successful multi-texture designs rely on color continuity. Select a smooth slab with veining or base tones that mirror the primary color of the textured ledger stone. Industry trends favor using the smooth slab for high-moisture zones (like the sink or stove) and transitioning to the ledger stone as a decorative border or full-height accent wall. To ensure a professional finish, install the smooth slab first to create a clean, level horizontal edge for the stone pieces to sit against.

Does a hybrid backsplash cost more than a single-material wall?

Typically, yes. Hybrid installations require higher labor costs due to the complexity of managing two different material thicknesses and the need for precision transition joints. You may also need to hire two different types of specialists: a slab fabricator for the smooth sections and a tile setter for the textured components. However, this approach can reduce overall material waste by allowing you to use high-end slab remnants for the focal point and more cost-effective stone for the secondary surfaces.

What is the best way to seal the joint between two different stone types?

Never use standard grout to bridge the gap between two different materials, as expansion and contraction will inevitably cause it to crack. The industry standard is to use a high-quality, 100% silicone sealant that is color-matched to the stone. This provides a flexible, waterproof barrier that accommodates the minute movements of the different stone densities while maintaining a seamless visual transition.

Will the difference in thickness affect my cabinet installation?

Yes, thickness is a critical factor in planning. Ledger stone is significantly deeper than a standard tile or 2cm slab, which can lead to the stone protruding past the front of the cabinet frames or interfering with electrical outlet plates. To avoid this, cabinets should be shimmed forward, or the stone should be strategically placed so that it does not impede cabinet door swings or appliance clearances. Always measure the total depth of the stone and mortar bed before finalizing cabinet placement.