Kutting hovedbok steinpaneler Kan virke som en skremmende oppgave, men med de riktige verktøyene og teknikkene blir den håndterbar og presis. Her er en trinn-for-trinn-guide som hjelper deg med å kutte hovedsteinspaneler effektivt.

-

Kina nye farger kvartsitt stablet steinpaneler

Kina nye farger kvartsitt stablet steinpaneler -

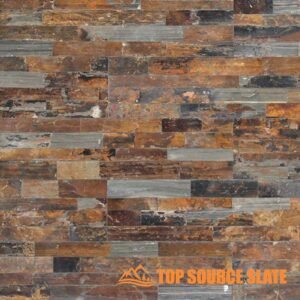

Grov rusten skifer stablet steinbokpanel 6 tommer. X 24 tommer.

Grov rusten skifer stablet steinbokpanel 6 tommer. X 24 tommer. -

Grov Alaska Gray Stacked Stone Ledger Panel 6 in. X 24 in.

Grov Alaska Gray Stacked Stone Ledger Panel 6 in. X 24 in. -

Grov sandstein stablet steinbokpanel 6 tommer. X 24 tommer.

Grov sandstein stablet steinbokpanel 6 tommer. X 24 tommer. -

Naturlig svart skifer grovt hovedbokspanel 6 tommer x 24 tommer.

Naturlig svart skifer grovt hovedbokspanel 6 tommer x 24 tommer. -

Sierra Blue Ledger Panel 6 in. X 24 tommer. Naturstein kvartsitt

Sierra Blue Ledger Panel 6 in. X 24 tommer. Naturstein kvartsitt -

California gullskifer naturlig avsats steinpaneler - 6 x 24

California gullskifer naturlig avsats steinpaneler - 6 x 24 -

Golden Harvest Slate Panel Ledger – 6 x 24

Golden Harvest Slate Panel Ledger – 6 x 24

-

Sandstein av beste kvalitet 3D Split Faced Fuiles for Interior and Exterior

Sandstein av beste kvalitet 3D Split Faced Fuiles for Interior and Exterior -

Engros pris rustikk kobberkvarts splitface mosaikkfliser

Engros pris rustikk kobberkvarts splitface mosaikkfliser -

Høykvalitets kinesisk gnisten med delt ansikt mosaikkfliser østers

Høykvalitets kinesisk gnisten med delt ansikt mosaikkfliser østers -

Kina Produksjon Oyster Riven Split Face Quartzite Mosaic -fliser

Kina Produksjon Oyster Riven Split Face Quartzite Mosaic -fliser -

Profesjonell produksjon rotia grå murstein delt ansikt mosaikkfliser 10*36cm

Profesjonell produksjon rotia grå murstein delt ansikt mosaikkfliser 10*36cm -

China Factory Royal White Split Face Ledger Panel

China Factory Royal White Split Face Ledger Panel -

Kina Factory Green Quartzite Split Face Mosaic Wall -fliser

Kina Factory Green Quartzite Split Face Mosaic Wall -fliser -

Kina produsent svart kvartsitt mini splitface fliser

Kina produsent svart kvartsitt mini splitface fliser

1. Verktøy du trenger

Før du starter, samle viktige verktøy:

- Våt sag med et diamantblad

- Vinkelkvern (for mindre eller detaljerte kutt)

- Sikkerhetsutstyr: briller, hansker og en maske for å beskytte mot støv og rusk

2. Forberedelse og sikkerhetstiltak

Når du skjærer hovedbok steinpaneler, sikkerhet må komme først. Slitasje vernebriller for å beskytte øynene dine mot rusk, øreplugger å beskytte mot støy, og tunge hansker For å forhindre skader fra skarpe steinkanter. Forsikre deg om at du kutter i et godt ventilert område for å minimere innånding av støv. En maske kan gi ekstra beskyttelse. Hvis du bruker elektriske verktøy som en våt sag eller kvern, hold vann borte fra strømkilder og sikre at arbeidsoverflaten din er solid og nivå for å unngå bevegelse under skjæring. Fest hovedboken steinpaneler med klemmer for å forhindre skifting.

Før du skjærer, må du måle to ganger og merk hovedboksen med en blyant, kritt eller en steinsammer. Ta hensyn til oppsettet for å minimere feil og avfall.

3. Skjær med en våt sag

EN våt sag er det mest effektive verktøyet for rene, rette kutt på Ledger Stone -paneler. Den våte saget bruker vann for å avkjøle bladet, redusere friksjonen og minimere støv. Følg disse trinnene:

- Sett opp: Forsikre deg om at den våte sagen er plassert på en flat overflate, helst utendørs eller i et godt ventilert område på grunn av vannspray og støv.

- Merking: Tegn en klar linje der du planlegger å kutte hovedfestet. Sørg for å justere dette merket med Saw's Guide.

- Kutting: Plasser steinpanelet på sagbordet, slik at det holder seg fast mot gjerdet. Begynn sakte å skyve steinen mot bladet, slik at sagen kan skjære uten å tvinge den. Bruk lett trykk for å forhindre at steinen flis.

- Vannforvaltning: Hold øye med vannreservoaret for å sikre kontinuerlig kjøling, da et overopphetet blad kan føre til ujevne kutt eller skade på steinen.

Etter å ha kuttet hovedfestet, inspiser kantene og, om nødvendig, glatte grove flekker med en vinkelkvern.

4. Bruke en vinkelkvern for presisjon

En vinkelkvern gir fleksibilitet og presisjon for mer intrikate kutt, for eksempel når du trenger å kutte rundt elektriske utsalgssteder eller trange hjørner. Vinkelkvernet er utstyrt med et diamantblad, og er ideell for å lage grunne, kontrollerte kutt.

- Preparat: Som med den våte sagen, bruk sikkerhetsutstyr, spesielt en maske, siden vinkelkverner genererer mye støv. Bruk klemmer for å feste hoveddeler steinpaneler, og forhindrer dem i å bevege seg under snittet.

- Skjæreprosess: Lag små, grunne pasninger over hovedboken. Påfør mildt trykk og la kvernen gjøre det meste av arbeidet. Unngå å tvinge bladet til å forhindre flis.

- Manøvrerbarhet: Vinkelkverner utmerker seg i områder der en rett sag ikke vil nå, og gir større manøvrerbarhet for stramme eller avrundede kutt. Vær oppmerksom på bladets retning, og kutt i korte utbrudd for å opprettholde kontrollen.

Når du bruker kvernen for finere detaljer, fokuser du på tålmodighet og presisjon for å unngå å overskutte hovedboken.

5. Viktige tips for jevn skjæring

- Hold bladet vått til enhver tid ved å oppdatere vannforsyningen ofte når du bruker en våt sag.

- Hvis du leier verktøy, kan du sjekke bladtilstanden for å unngå ujevne kutt.

- Planlegg kutt nøye for å minimere avfall og opprettholde det naturlige utseendet til hovedsteinspaneler.

6. Etterbehandling og Installasjon

Når den er kuttet, glatt eventuelle grove kanter med vinkelsliperen om nødvendig. Rengjøre hovedsteinpaneler for å fjerne støv eller rester før installasjon. Følg layoutplanen for å installere panelene sømløst.

7. Ledger Stone Panels kutter sikkerhetsforholdsregler

- Følg produsentens instruksjoner: Forsikre deg alltid om at skjæreutstyret blir brukt i henhold til Produsentens retningslinjer. Riktig oppsett og håndtering reduserer risikoen for ulykker og skader på utstyret.

- Bruk beskyttende briller: Å bruke godkjente sikkerhetsglass er avgjørende for å forhindre at øyeskader flyr rusk når du kutter hovedfestet.

- Bruk en åndedrettsvern: Bruk standardgodkjente åndedrettsvern, spesielt når du kutter produserer luftbåren støv. Dette er viktig for å beskytte mot skadelige støvpartikler. En minimum engangsprengsedrettsvern skal være tilstrekkelig for de fleste oppgaver.

- Hørselsvern: Kutting av hovedsteinssteinpaneler kan være høye, så det å bruke ørebeskyttelse som øreplugger eller øremuffer hjelper til med å forhindre hørselsskader.

- Hold arbeidsområdet rent: Før en sag, fjern eventuelle avskjærte stykker fra skjæreområdet for å unngå farer. Dette reduserer sjansen for å skli eller snuble over rusk mens du skjærer.

- Sørg for et trygt arbeidsmiljø: Tillat bare de som har riktig sikkerhetsutstyr i nærheten av skjæreområdet. Ubeskyttede personer bør holdes unna for å unngå eksponering for flygende rusk.

- Utendørs skjæring og ventilasjon: Utfør alltid Ledger Stone -panelet som skjærer utendørs for å forhindre at støv samler seg innendørs. Lukk nærliggende vinduer og dører for å forhindre at støv kommer inn i bygninger under skjæring.

- Våt skjæring og støvkontroll: For å undertrykke støv, bruk våtskjærende teknikker. Samle ruskene før det tørker ut, og kast det trygt. Hvis våte metoder er upraktiske, bruk et eksosventilasjonssystem og vurder et høyeffektiv partikkelformig filterstøvsuger for å samle støv. Unngå å feie tørt rusk med en kost; I stedet kan du samle den med fuktige filler for å forhindre at støv blir luftbåren igjen.

Disse utvidede sikkerhetstiltakene sikrer både personlig beskyttelse og et rent, trygt arbeidsområde når du kutter hovedfestet.

Stacked Stone: A Complete Buyer's Guide【oppdatering】

Hvordan installere stablet stein eller hyllestein

Installasjonsveiledning for stablet steinfliser

Hvordan måle for stablede steinfinerpaneler

Konklusjon

Kutting hovedbok steinpaneler er en enkel prosess hvis du har riktig utstyr og følger sikkerhetsforholdsregler. Enten du bruker en våt sag for rene kutt eller en vinkelkvern for detaljert arbeid, vil du ta deg tid og planlegge kuttene dine føre til profesjonelle resultater.

Hvis du leter etter Ledger steinpanelprodusenter og leverandører, anbefaler vi å sjekke produktene våre.

- Mosaikkmedaljonger 1010 produkter

- Crazy Paving Flaggstein 1414 produkter

- Tilfeldig løs stein 1818 produkter

- Dry Stack Stone 2424 produkter

- Foss stablet stein 1717 produkter

- Marmor stablet stein 1010 produkter

- Veggfliser med delte ansikter 1515 produkter

- Ledgestone veggkledning 2828 produkter

- Stablet stein 3737 produkter

Vi har mer enn 15 års eksporterfaring og tilbyr prøver før bestilling. For å få et tilpasset tilbud,Kontakt oss nå!