Cięcie kamienne panele księgi głównej Może wydawać się zniechęcającym zadaniem, ale dzięki odpowiednim narzędziom i technikom staje się możliwe do opanowania i precyzyjne. Oto przewodnik krok po kroku, który pomoże ci skutecznie wyciąć panele kamienne księgi.

-

Chiny nowe kolory kwarcytowych paneli kamiennych

Chiny nowe kolory kwarcytowych paneli kamiennych -

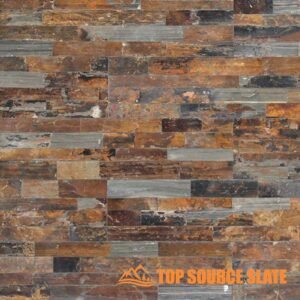

Panel księgi kamiennej z szorstkiego, zardzewiałego łupka o wymiarach 6 cali x 24 cale.

Panel księgi kamiennej z szorstkiego, zardzewiałego łupka o wymiarach 6 cali x 24 cale. -

Szorstki, szary, ułożony w stos kamienny panel księgi głównej o wymiarach 6 cali x 24 cale.

Szorstki, szary, ułożony w stos kamienny panel księgi głównej o wymiarach 6 cali x 24 cale. -

Panel kamienny z szorstkiego piaskowca o wymiarach 6 cali x 24 cale.

Panel kamienny z szorstkiego piaskowca o wymiarach 6 cali x 24 cale. -

Panel księgi z naturalnego, czarnego łupka, szorstki, 6 cali x 24 cale.

Panel księgi z naturalnego, czarnego łupka, szorstki, 6 cali x 24 cale. -

Panel księgi Sierra Blue 6 cali x 24 cale. Kamień naturalny Kwarcyt

Panel księgi Sierra Blue 6 cali x 24 cale. Kamień naturalny Kwarcyt -

Panele z naturalnego kamienia z łupka kalifornijskiego - 6 x 24

Panele z naturalnego kamienia z łupka kalifornijskiego - 6 x 24 -

Księga panelowa z łupków złotych zbiorów – 6x24

Księga panelowa z łupków złotych zbiorów – 6x24

-

Najwyższej jakości płytki łupane 3D z piaskowca do wnętrz i na zewnątrz

Najwyższej jakości płytki łupane 3D z piaskowca do wnętrz i na zewnątrz -

Cena hurtowa rustykalna mozaika kwarcowo-miedziana z dzieloną powierzchnią

Cena hurtowa rustykalna mozaika kwarcowo-miedziana z dzieloną powierzchnią -

Wysokiej jakości chińska mozaika z dzieloną powierzchnią, typu ostryga

Wysokiej jakości chińska mozaika z dzieloną powierzchnią, typu ostryga -

Chiny produkują mozaikę kwarcytową z dzieloną powierzchnią ostryg

Chiny produkują mozaikę kwarcytową z dzieloną powierzchnią ostryg -

Profesjonalna produkcja mozaiki z szarej cegły rotia z dzieloną powierzchnią 10 * 36 cm

Profesjonalna produkcja mozaiki z szarej cegły rotia z dzieloną powierzchnią 10 * 36 cm -

Fabryka w Chinach, panel księgi głównej z dzieloną twarzą w kolorze królewskiej bieli

Fabryka w Chinach, panel księgi głównej z dzieloną twarzą w kolorze królewskiej bieli -

Fabryczne płytki ścienne z mozaiką z zielonego kwarcytu w Chinach

Fabryczne płytki ścienne z mozaiką z zielonego kwarcytu w Chinach -

Producent chińskiej płytki z czarnego kwarcytu mini z dzieloną powierzchnią

Producent chińskiej płytki z czarnego kwarcytu mini z dzieloną powierzchnią

1. Narzędzia, których będziesz potrzebować

Przed rozpoczęciem zbierz niezbędne narzędzia:

- Mokra piła z diamentowym ostrzem

- Młynek do kątowy (dla mniejszych lub szczegółowych cięć)

- Sprzęt bezpieczeństwa: gogle, rękawiczki i maska do ochrony przed kurzem i resztkami

2. Środki przygotowania i bezpieczeństwa

Podczas cięcia kamienne panele księgi głównej, Bezpieczeństwo musi być najważniejsze. Nosić okulary ochronne Aby chronić oczy przed gruzami, zatyczki do uszu chronić przed hałasem i Ciężkie rękawiczki Aby zapobiec obrażeniu z ostrych krawędzi kamiennych. Upewnij się, że wycinasz w dobrze wentylowanym obszarze, aby zminimalizować wdychający kurz. Maska może zapewnić dodatkową ochronę. Jeśli używasz narzędzi elektrycznych, takich jak mokra piła lub młynek, trzymaj wodę z dala od źródeł zasilania i upewnij się, że powierzchnia robocza jest solidna i poziom, aby uniknąć ruchu podczas cięcia. Zabezpiecz panele kamienne księgowości za pomocą zacisków, aby zapobiec zmianie.

Przed cięciem, zmierz dwukrotnie i zaznacz panele kamienne księgi ołówkiem, kredą lub kamiennym znacznikiem. Weź pod uwagę układ, aby zminimalizować błędy i marnotrawstwo.

3. Cięcie mokrą piła

A mokra piła jest najskuteczniejszym narzędziem do czystych, prostych cięć na kamiennych panelach. Mokra piła wykorzystuje wodę do ochłodzenia ostrza, zmniejszenia tarcia i zminimalizowania pyłu. Wykonaj następujące kroki:

- Organizować coś: Upewnij się, że mokra piła jest umieszczona na płaskiej powierzchni, najlepiej na zewnątrz lub w dobrze wentylowanym obszarze z powodu sprayu wody i kurzu.

- Cechowanie: Narysuj wyraźną linię, w której planujesz wyciąć panele kamienne księgi. Upewnij się, że wyrównaj ten znak do przewodnika SAW.

- Cięcie: Umieść kamienny panel na stole piły, upewniając się, że pozostaje mocno przy ogrodzeniu. Zacznij powoli popychać kamień w kierunku ostrza, pozwalając piły, bez wymuszania go. Użyj lekkiego ciśnienia, aby zapobiec odpryskiwaniu kamienia.

- Zarządzanie wodą: Miej oko na zbiornik wodny, aby zapewnić ciągłe chłodzenie, ponieważ przegrzane ostrze może prowadzić do nierównomiernych cięć lub uszkodzeń kamienia.

Po przecięciu paneli kamiennych sprawdź krawędzie i, w razie potrzeby, wygładzaj szorstkie plamy za pomocą młynek do kąta.

4. Używając szlifierki kątowej do precyzji

Młynek do kątów zapewnia elastyczność i precyzję dla bardziej skomplikowanych cięć, na przykład gdy trzeba przecinać gniazda elektryczne lub ciasne zakręty. Wyposażony w diamentowe ostrze, młynek do kątowy jest idealny do robienia płytkich, kontrolowanych cięć.

- Przygotowanie: Podobnie jak w przypadku mokrej piły, noszenie sprzętu bezpieczeństwa, zwłaszcza maski, ponieważ szlifierki kątowe wytwarzają dużo pyłu. Użyj zacisków, aby zabezpieczyć panele kamienne księgi, uniemożliwiając im poruszanie się podczas cięcia.

- Proces cięcia: Wykonaj małe, płytkie podania nad kamiennymi paneli księgi. Nakładaj delikatną presję i pozwól szlifierowi wykonać większość pracy. Unikaj zmuszania ostrza, aby zapobiec odpryskiwaniu.

- Manewrowość: Millery kątowe wyróżniają się w obszarach, w których prosta piła się nie osiągnie, oferując większą manewrowość na ciasne lub zaokrąglone cięcia. Uważaj na kierunek ostrza i pokrój w krótkich seriach, aby utrzymać kontrolę.

Używając szlifierki do drobniejszych detali, skup się na cierpliwości i precyzji, aby uniknąć nadmiernego wycinania paneli kamiennych księgi.

5. Ważne wskazówki dotyczące gładkiego cięcia

- Utrzymuj ostrze przez cały czas, często odświeżając zaopatrzenie w wodę podczas korzystania z mokrej piły.

- Jeśli wynajmuje narzędzia, sprawdź warunek ostrza, aby uniknąć nierównomiernych cięć.

- Uważnie zaplanuj cięcia, aby zminimalizować odpady i zachować naturalny wygląd paneli kamiennych księgi.

6. Wykończenie i Instalacja

Po wycięciu w razie potrzeby wygładzaj szorstkie krawędzie młynem do kąta. Przed instalacją wyczyść panele kamienne księgi, aby usunąć kurz lub pozostałość. Postępuj zgodnie z planem układu, aby bezproblemowo zainstalować panele.

7. Kamienne panele Kamieni

- Postępuj zgodnie z instrukcjami producenta: Zawsze upewnij się, że sprzęt do cięcia jest używany zgodnie z Wytyczne producenta. Właściwa konfiguracja i obsługa zmniejszają ryzyko wypadków i uszkodzenia sprzętu.

- Użyj okularów ochronnych: Noszenie zatwierdzonych okularów bezpieczeństwa ma kluczowe znaczenie dla zapobiegania urazom oczu latających resztek podczas cięcia paneli kamiennych księgi.

- Noś respirator: Użyj standardowych respiratorów, zwłaszcza podczas cięcia produkuje pył unoszący się w powietrzu. Jest to niezbędne do ochrony przed szkodliwymi cząsteczkami pyłu. Minimalny jednorazowy respirator PI powinien wystarczyć do większości zadań.

- Ochrona słuchu: Cięcie kamiennych paneli może być głośne, więc noszenie ochrony ucha, takich jak zatyczki do uszu lub uszu, pomaga zapobiec uszkodzeniom słuchu.

- Utrzymuj obszar roboczy w czystości: Przed uruchomieniem piły usuń wszelkie odcięte kawałki z obszaru cięcia, aby uniknąć zagrożeń. Zmniejsza to szansę poślizgnięcia się lub potykania gruzu podczas cięcia.

- Zapewnij bezpieczne środowisko pracy: Pozwól tylko osobom noszącym odpowiednie sprzęt bezpieczeństwa w pobliżu obszaru cięcia. Osoby bez zabezpieczenia należy trzymać z daleka, aby uniknąć narażenia na latające gruz.

- Cięcie i wentylacja na zewnątrz: Zawsze wykonuj kamienne panele kadrowe na zewnątrz, aby zapobiec gromadzeniu się pyłu w pomieszczeniu. Zamknij pobliskie okna i drzwi, aby zapobiec wchodzeniu do budynków podczas cięcia.

- Mokre cięcie i kontrola pyłu: Aby tłumić kurz, użyj technik cięcia na mokro. Zbierz zanieczyszczenia, zanim wyschną i bezpiecznie je pozbawiaj. Jeśli metody mokre są niepraktyczne, użyj układu wentylacji spalin i rozważ wysokowydajny odkurzacz filtra cząstek stałych, aby zebrać kurz. Unikaj zamiatania suchych zanieczyszczeń z miotłą; Zamiast tego zbierz go wilgotnymi szmatami, aby zapobiec ponownej powietrza pyłu.

Te rozszerzone środki bezpieczeństwa zapewniają zarówno ochronę osobistą, jak i czystą, bezpieczną przestrzeń roboczą podczas cięcia paneli kamiennych księgi.

Ułożony kamień: kompletny przewodnik dla kupujących 【aktualizacja】

Jak zainstalować ułożony kamień lub kamień półkowy

Wytyczne dotyczące montażu ułożonych płytek kamiennych

Jak zmierzyć ułożone panele z forniru kamiennego

Wniosek

Cięcie kamienne panele księgi głównej jest prostym procesem, jeśli masz odpowiedni sprzęt i przestrzegasz środków bezpieczeństwa. Niezależnie od tego, czy używasz mokrej piły do czystych cięć, czy młynek do kąta do szczegółowej pracy, nie spieszenie czasu i planowanie cięć doprowadzi do profesjonalnych wyników.

Jeśli szukasz Producenci i dostawcy paneli kamienia księgi, polecamy sprawdzić nasze produkty.

- Medaliony mozaikowe 1010 produktów

- Szalony Brukowy Fliz 1414 produktów

- Losowy luźny kamień 1818 produktów

- Kamień z suchego stosu 2424 produkty

- Wodospad Ułożony Kamień 1717 produktów

- Marmur Ułożony Kamień 1010 produktów

- Płytki ścienne dzielone 1515 produktów

- Okładzina ścienna Ledgestone 2828 produktów

- Ułożony Kamień 3737 produktów

Mamy ponad 15-letnie doświadczenie w eksporcie i oferujemy próbki przed złożeniem zamówienia. Aby otrzymać indywidualną wycenę,Skontaktuj się z nami teraz!