Small kitchen optimization becomes a logistical hurdle when heavy traditional stone reduces usable square footage and adds excessive weight to vertical surfaces. Selecting an inappropriate material thickness often results in wasted inches on countertops and requires additional labor for structural reinforcement, which eats into project margins. High-end renovations require a balance between the aesthetic of natural textures and the physical realities of a restricted floor plan where every inch dictates the functionality of the space.

We address how slim stone veneer profiles provide the texture of deep-cut stone while maintaining the clearance needed for appliances and movement. This technical review covers the use of quartzite for light reflection, the impact of panel orientation on visual volume, and the specific thin-set requirements for beverage station accents. These methods provide a standard for maximizing luxury in environments where spatial constraints often limit design choices.

Can a Massive Texture Work in a Limited Square Footage Kitchen?

Applying massive stone textures in compact kitchens requires a disciplined “zone-specific” approach to prevent the rugged profile from overwhelming the room’s proportions.

Integrating heavy textures into small-scale designs is a matter of scale and restraint. While homeowners often fear that a thick, split-face stone will “swallow” a small room, empirical design data from 2026 shows that bold textures actually provide the visual weight needed to make a small space feel intentional and high-end. The key lies in selecting the right material and limiting its application to a singular, high-impact focal point.

Creating a Single Focal Point with Rough-Cut Stone

Designers now recommend limiting the Rough Series to one specific zone, such as the backsplash behind the range or the front of a kitchen island. Deep textures create dramatic shadows that provide character, but applying them to every wall in a small space feels overwhelming. By treating the stone as a standalone architectural feature, you allow the material to breathe without cluttering the environment.

- Concentrating the Rough Series in a 30-inch to 36-inch range zone creates a powerful anchor for the room.

- Natural shadows from the split-face surface add depth, making flat walls appear more three-dimensional.

- Selective application preserves the kitchen’s functionality while maintaining a premium B2B design aesthetic.

Balancing Deep Textures with Minimalist Cabinetry

Contrast is the most effective tool for ensuring heavy stone textures do not dominate a compact layout. We suggest pairing the heavy texture of stacked stone with flat-panel, handle-less cabinets. This juxtaposition of rugged natural stone against smooth, polished surfaces helps the eye distinguish different functional zones within the kitchen. Using a Flat Series for secondary walls ensures the space retains the authenticity of natural stone without excessive bulk.

- Flat-panel cabinetry provides a “visual rest” that balances the complexity of the stone.

- Same-batch quarry consistency ensures that the colors remain uniform, preventing a “patchy” look that can make small rooms feel smaller.

- Using CNC diamond-blade precision on the stone edges creates tight, clean lines that complement modern minimalist hardware.

Using Light-Toned Stone to Enhance Spatial Perception

Color selection significantly impacts how large or small a kitchen feels. Materials like Glacier White Stacked Stone (Quartzite) or Arctic White reflect more light, opening up dark corners in small 2026 kitchen designs. These reflective natural stone surfaces amplify both natural and LED task lighting, which makes limited square footage feel more expansive and airy.

- White and off-white quartzites offer the desired texture while maintaining a bright, open atmosphere.

- Light-toned stone acts as a mirror for under-cabinet lighting, eliminating shadows that contribute to a “cramped” feeling.

- Materials like Arctic Golden or Glacier White provide high UV stability, ensuring the brightness does not fade over time.

Vertical Panel Orientation to Extend Sightlines

Strategic installation directions trick the eye into perceiving more height and volume. Installing the Pencil Series or other linear stone panels vertically draws the eye toward the ceiling, creating an illusion of height. Running these panels from the countertop all the way to the ceiling provides a seamless look that removes visual breaks, making small kitchens feel well-planned rather than cramped.

- Vertical orientation emphasizes the room’s height, which is often the most underutilized dimension in small kitchens.

- Utilizing Z-Shape interlocking technology eliminates visible vertical joints, creating a continuous stone surface.

- Matching L-corners ensure a professional wrap-around finish on any exposed wall ends or structural pillars.

Choosing the “Slim Profile” Stone: Saving Precious Inches on the Counter

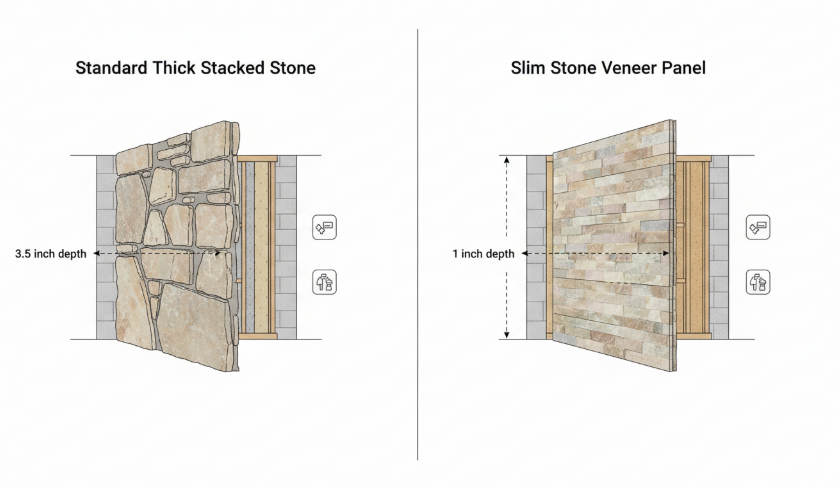

Thin-profile natural stone panels solve the spatial conflict between architectural texture and narrow countertop clearance by reducing the backsplash footprint to less than 1.25 inches.

Standard heavy-cut stone often crowds narrow galley kitchens, leaving little room for small appliances or food preparation. We engineer the Flat Series specifically for these tight tolerances. By maintaining a thickness between 0.75 and 1.25 inches, these panels provide the rugged depth of natural masonry while remaining clear of faucet handles and appliance depths. This slim footprint ensures that even the most compact 2026 modern layouts retain their functional work surfaces.

| Specification | Standard Stacked Stone | Top Source Slim Series |

|---|---|---|

| Installation Thickness | 1.5″ – 3.5″ (40mm+) | 0.75″ – 1.25″ (20mm-30mm) |

| Average Weight | 15 – 25 lbs/sq.ft | 8 – 12 lbs/sq.ft |

| Structural Requirement | Wall Footings/Reinforcement | Standard Cement Board |

Lightweight Composition and Structural Efficiency

Reducing the weight of natural stone allows for faster installation in residential settings where wall reinforcement is not an option. Our panels weigh between 8 and 13 pounds per square foot, making them compatible with standard apartment framing and interior drywall backed by cement board. We utilize a high-strength epoxy resin bond to secure each stone strip to the substrate, ensuring that the reduced mass does not compromise the structural integrity or the “dry-stack” aesthetic.

- Eliminate the need for costly wall footings or structural metal ties during kitchen renovations.

- Install directly onto sound masonry or cement-based substrates with standard thin-set mortars.

- Maintain permanent adhesion in high-moisture environments using our factory-engineered substrate bonding.

Precision Infrared Cutting for Tight Tolerances

Small kitchens leave no room for visual clutter or bulky grout lines. We employ CNC diamond-blade cutting to achieve exact dimensions, facilitating a seamless Z-shape interlocking system. This precision engineering ensures that each panel fits tightly with the next, camouflaging vertical joints and creating a continuous architectural surface that expands the room’s perceived width. For tight corners, our matching L-shaped corner pieces provide a professional wrap-around finish without the need for complex, on-site mitering that often adds unnecessary bulk.

Material Durability in High-Traffic Zones

Natural slate and quartzite offer superior resistance to the typical wear found in active kitchens. Unlike synthetic veneers, natural stone maintains its color integrity under high-heat conditions and UV exposure from windows. We recommend applying a pH-neutral sealer to these slim panels to prevent staining from cooking oils. Quartzite, in particular, remains a top choice for windowless kitchens due to its high density and light-reflective properties, which brighten workspace areas while resisting moisture penetration.

- Quartzite options like Glacier White enhance brightness in dark corners through natural mineral reflectivity.

- Slate varieties provide high heat resistance for backsplashes located directly behind professional-grade ranges.

- Non-fading properties ensure the stone backsplash looks identical after a decade of kitchen use.

Premium Factory-Direct Stacked Stone Panels

Light Reflective Stones: Using Quartzite to Brighten Dark Corners

Strategic selection of quartzite with natural crystalline properties can increase light bounce by up to 40%, transforming recessed kitchen corners into bright, functional workspaces without additional structural lighting.

Natural Crystalline Reflection in Quartzite Panels

Natural quartzite serves as a functional light-management tool rather than a purely decorative element. Unlike matte materials like slate or limestone, quartzite contains quartz crystals that catch and redirect light. In the context of 2026 design standards, maximizing existing ambient light is a priority for compact kitchens. Utilizing the Pencil Series in quartzite creates a multi-faceted surface where each narrow strip of stone catches light from different angles, effectively neutralizing shadows in areas with limited window access.

| Material Selection | Reflectivity Index | Best Small Kitchen Application |

|---|---|---|

| Glacier White Quartzite | High (Crystalline) | Windowless backsplashes and dark corners |

| Midnight Slate | Low (Matte) | Accents in high-lumen, open areas |

| Arctic Golden Quartzite | Medium-High | Warmth and light bounce in galley layouts |

Top Source Stone focuses on sourcing these materials from specific quarry veins to ensure the crystal density remains consistent. This consistency prevents “flat spots” on the wall where light fails to reflect. When contractors install these panels, the natural cleft finish provides enough topographical variance to scatter light, which softens the harshness of artificial recessed lighting often found in apartment kitchens.

Integrating LED Backlighting with Translucent Stone

For extreme cases where natural light is non-existent, translucent quartzite varieties like Cristallo function as massive light diffusers. Modern manufacturing techniques utilize high-strength epoxy resins that maintain bond integrity even under the low-grade heat generated by integrated LED systems. By installing thin LED strips behind these stone panels, the backsplash becomes an active light source.

- Eliminates the “cave effect” in tight galley kitchens by providing a glow that originates from the wall surface itself.

- Serves as secondary task lighting for countertop food preparation.

- Highlights the internal geological veining, adding visual depth without occupying physical space.

Color Palettes for Luminous Kitchen Design

Color selection dictates the perceived volume of a small space. Light-colored stacked stone, such as Alaska Gray or Glacier White from the Big 10 inventory, can reflect up to 40% more light than darker alternatives like soapstone or carbon slate. Pairing these light-hued natural stone panels with high-gloss cabinetry creates a layered aesthetic that pushes the boundaries of the room outward.

Precision-cut interlocking panels play a vital role here. Using Z-shape or S-shape designs ensures a seamless surface that prevents dark grout lines from breaking up the reflection of light. Top Source Stone utilizes CNC diamond-blade edges to achieve a tight “male-female” connection, creating a continuous plane of stone. This lack of visible joints allows the eye to travel across the wall without interruption, making a compact kitchen wall appear significantly longer and brighter.

Vertical vs. Horizontal Panel Orientation: Which Makes the Kitchen Look Larger?

Directional orientation dictates perceived volume; horizontal layouts stretch narrow floor plans while vertical stacks counteract the compression of low ceilings.

Horizontal Alignment for Visual Width Expansion

Installing natural stacked stone panels horizontally mimics the horizon line, drawing the eye across the room to create an illusion of greater width. This layout works particularly well in narrow galley kitchens where the goal is to push the walls outward visually. By aligning the long axis of a 6″ x 24″ panel with the countertop, you create a continuous stream of texture that eliminates the choppy feel of smaller tiles.

- Horizontal lines guide the gaze along the perimeter, making narrow galley kitchens feel more open.

- Our interlocking Z-shape system ensures these horizontal lines remain seamless and unbroken, camouflaging vertical joints with CNC diamond-blade precision.

- Contemporary 2026 design trends favor horizontal orientation to complement long, low-profile cabinetry and modern minimalist aesthetics.

| Orientation Strategy | Primary Spatial Impact | Recommended Panel Type |

|---|---|---|

| Horizontal Alignment | Stretches the width of narrow walls | Interlocking Z-Shape (Standard) |

| Vertical Alignment | Increases perceived ceiling height | Pencil Series / Slim Profile |

| Corner Continuity | Eliminates visual breaks that shrink rooms | Matching L-Corners |

Vertical Orientation to Enhance Ceiling Height

Orienting stone panels vertically pulls the vision upward, which helps kitchens with low ceilings feel airy. This rhythmic, upward flow provides a sense of loftiness in limited square footage. For multi-unit residential projects or apartments where ceiling heights are often fixed at eight feet, a vertical stack can make the space feel significantly more grand without structural changes.

- Vertical patterns provide a sense of grandeur and loftiness in limited square footage.

- The thin, elongated stones in our Pencil Series work effectively in vertical layouts by emphasizing height.

- Top-tier designers use vertical orientation for full-height backsplashes to maximize vertical real estate and create a focal point.

Selecting the Right Texture for Each Direction

Texture interacts with kitchen lighting differently depending on the panel direction. Flat series panels in a horizontal layout provide a sleek, streamlined look that minimizes visual clutter—a critical requirement for small spaces. Conversely, Rough series panels in a vertical layout add dramatic shadows that emphasize height, though these should be used on single accent walls to avoid encroaching on the physical floor space.

- Flat series panels provide a streamlined look that reduces “visual noise” in compact areas.

- Rough series panels add depth and shadow, working best as a vertical feature behind a range.

- Light-colored stones like Glacier White or Arctic Golden quartzite amplify the spatial benefits of either orientation by reflecting more light.

Strategic Placement for Maximum Spatial Impact

Determining where the stone starts and stops ensures the orientation actually serves the goal of making the kitchen look larger. Running horizontal panels into the corners and around transitions eliminates sharp visual breaks that can shrink a room. We provide matching L-shaped corner pieces for every series to maintain the continuity of the chosen direction across different planes, ensuring a professional wrap-around finish that keeps the eye moving.

- Running panels into the corners eliminates sharp visual breaks that interrupt the room’s flow.

- Pre-fabricated 90-degree corners maintain color and texture synchronization at wall transitions.

- Focusing vertical orientation on a single accent wall prevents the texture from overwhelming a small space while still providing the desired height boost.

Using Stone for a Small Coffee Bar or Beverage Station Accent

Natural stone provides a heat-resistant, non-combustible foundation that transforms compact beverage stations into high-end architectural focal points without sacrificing valuable counter depth.

Thermal Stability for Espresso and Brewing Equipment

Commercial-grade espresso boilers and steam wands generate localized heat that frequently compromises standard drywall or synthetic panels. Natural stone acts as a functional heat shield for the beverage zone, withstanding temperatures up to 1,200°F without cracking or discoloration. This thermal stability makes it an essential safety choice for backing high-output brewing equipment in 2026 residential setups.

- Natural stone panels protect walls from the constant heat cycles typical of professional espresso machines.

- Non-combustible properties provide a safer environment for electrical brewing stations and hot water dispensers.

- Dense quartzite and granite resist warping or moisture damage caused by frequent hot steam exposure.

Maximizing Vertical Interest with Thin Ledger Panels

In space-constrained coffee nooks, every inch of counter depth is critical. Using slim-profile ledger panels allows for high-impact texture without the bulk of traditional thick stone. Interlocking Z-shaped panels create a continuous, professional appearance that eliminates visible vertical joints, making even the smallest alcove feel like a custom-built architectural feature.

- Z-shaped interlocking designs create a seamless finish that camouflages the installation substrate in tight corners.

- The Flat Series maintains a clean-lined aesthetic that prevents small beverage zones from feeling visual cluttered.

- Orienting stone panels vertically draws the eye upward, creating the illusion of height in compact kitchen zones.

Texture and Visual Focus for Secondary Prep Areas

Small secondary prep areas provide the perfect opportunity to experiment with intricate textures like the Pencil Series. These linear, high-detail stone patterns add a sense of luxury and movement that larger walls might find overwhelming. By sourcing directly from the same quarry vein, we ensure hue uniformity that creates a cohesive, high-end look for these specialized stations.

- Pencil Series stone adds intricate detail that serves as a sophisticated backdrop for modern coffee gear.

- Natural variations in slate and marble offer a unique aesthetic that “faux” materials cannot replicate.

- Strategically placed stone accents increase tangible property value by creating a luxury cafe atmosphere at home.

Effective Sealing and Maintenance for Daily Use

Daily coffee preparation inevitably leads to acidic spills and oil splatters from grinders. Applying a high-quality sealant to natural stone creates a protective hydrophobic barrier that prevents these pigments from staining the material. Unlike painted walls that require frequent repainting, sealed stone remains hygienic and keeps its original texture with minimal effort.

- Professional sealants protect against coffee oils and acidic pigments in beverage preparation areas.

- Cleaning requires only water and a soft brush, making it ideal for high-use beverage stations.

- Natural stone retains its structural integrity and color indefinitely, outlasting synthetic or painted alternatives.

Conclusion

Small kitchens benefit from slim stone profiles that preserve counter space while adding high-end natural texture. Selecting light-reflective quartzite and specific panel orientations helps create an open, bright atmosphere in limited square footage. These design choices ensure that premium architectural finishes remain accessible for urban apartments and compact residential projects.

Review our Big 10 inventory to find the ideal slim-profile materials for your upcoming inventory needs. You can contact our team to request technical specifications or a physical sample kit for your showroom.

Frequently Asked Questions

Will a stone backsplash make my small kitchen feel too dark?

Not necessarily. While massive textures require strategic application, using light-colored stone and reflective materials actually amplifies light and makes small kitchens feel larger. By balancing textured stone with smooth surfaces—like matte cabinets—you create depth and visual interest without absorbing all the room’s light.

What is the thinnest stacked stone available for backsplashes?

The thinnest options currently available are ultra-thin natural stone veneers, which range from 1/16″ to 1/8″ thick. These consist of a real stone layer bonded to a fiberglass or fabric backing. For traditional rigid stacked stone panels, “thin-cut” options are typically manufactured at a thickness of 1/2″ to 3/4.

How to maximize counter space when using thick stone veneer?

To maximize every inch of counter depth, opt for a thin-set mortar application and select “low-profile” ledger panels. You can also “pocket” the stone into the wall by removing the existing drywall and mounting the stone directly to the studs (using a thin cement backer board), which can gain you an additional 1/2 inch of workspace.

Best stone colors for a kitchen with no windows?

For windowless kitchens, prioritize stones like White Marble, Light Travertine, or Quartzite in shades of cream, off-white, or soft silver. Stones with natural crystalline inclusions or a polished finish are ideal for these spaces, as they catch and scatter artificial light from under-cabinet LEDs and overhead fixtures.

Is stacked stone too heavy for an apartment kitchen wall?

Most natural stacked stone panels weigh between 8 and 12 pounds per square foot, which standard drywall can support if properly installed with a high-quality thin-set. For apartment dwellers concerned about weight or structural integrity, “micro-ledger” panels or lightweight stone veneers provide the same aesthetic at a significantly lower weight profile.