Cutting Outlets & Trimming errors in natural stone installations lead to costly rework, code violations, and compromised wall integrity that directly reduce project profitability. Poorly executed outlet cuts create visible gaps and structural weaknesses, increasing labor time and warranty claims for contractors.

This analysis benchmarks Top Source Stone’s CNC diamond-blade precision cutting against industry standards for tight tolerances and interlocking panel craftsmanship. We assess material consistency and minimum order quantities to support electricians and masons securing reliable, scalable supply chains for المنشآت الحجرية المكدسة.

Why Ugly Outlet Cuts Ruin a Professional Natural Stone Wall

Ugly outlet cuts undermine aesthetics, weaken structural integrity, and cause code violations, damaging the quality and durability of natural stone walls.

Visual Impact and Aesthetic Compromise

Oversized or poorly aligned outlet cutouts create visible gaps and disrupt trim alignment, which distract from the natural stone’s visual appeal. Since natural stone walls often serve as focal points, these flaws become permanent and cannot be hidden after installation. When cutouts exceed precise dimensions, installers resort to makeshift fixes like wooden spacers or oversized outlet covers, which stand out rather than blend in.

Installation Challenges and Code Compliance

Cutting through 4 to 6 inches of stone and mortar demands precision to avoid weakening the wall structure. Mistakes are difficult to correct due to the hardness of stone, and large errors require visible workarounds that compromise appearance. Additionally, when الحجر الطبيعي thickens wall surfaces, standard electrical outlet boxes do not fit flush, resulting in gaps that violate electrical codes. Professionals use special spacers to safely extend boxes, but this adds complexity and cost to the installation process.

How to Measure and Mark Stone Panels with 100% Accuracy

True 100% accuracy is unachievable with natural stone; calibrated tools and templating tech ensure professional precision within industry standards.

Understanding Industry Measurement Standards and Tolerances

الألواح الحجرية الطبيعية have inherent variability. The industry accepts specific tolerances depending on finish type to balance quality and the material’s natural characteristics.

- Flatness tolerance by finish: ±1.5 mm for smooth finishes, ±3 mm for multi-cut finishes (4-cut, 6-cut, 8-cut), ±5 mm for flamed or coarse stipple finishes, ±25 mm for rough cut finishes.

- Dimension-specific tolerances: Chamfers greater than 6 mm have a tolerance of -0 / +1.5 mm, bullnose or semi-bullnose edges (thickness ≤30 mm) allow ±0.8 mm variation.

- Joint widths: Allowed to vary ±25% of the specified width, with a minimum tolerance of ±0.8 mm.

- Accepting these tolerances prevents unrealistic expectations and accounts for natural stone variability while maintaining installation quality.

Applying Precision Techniques and Tools for Measurement and Marking

Precision starts with using the right instruments and technologies, combined with proper marking methods to ensure clean cuts on stone panels.

- Measurement tools: Calibrated tape measures are acceptable for general checks, but calipers or feeler gauges should be used for finer accuracy.

- Take care not to bend or loosen the tape measure’s end hook, a common source of measurement error.

- Laser templating systems: These generate highly accurate digital templates by scanning surfaces, reducing errors compared to traditional cardboard or plastic templates.

- Stable work surfaces and guide rails: Use setups like the Alpha guide rail with wheels to maintain straight, precise cutting lines during panel fabrication.

- Mark cutting lines carefully with standard spacing methods. For example, on limestone drip edges, mark a centerline ¾ to 1 inch from the edge, then measure 3/16 inch on either side to guide multiple light saw passes for a clean finish.

Premium Stacked Stone for Contractors

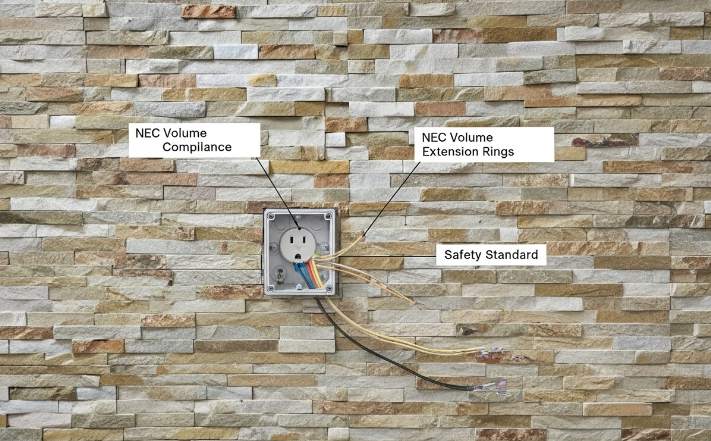

Using Box Extenders: The Safety Requirement Nobody Mentions

Box extenders must meet specific NEC regulations including limits on extension rings and volume compliance to prevent electrical hazards and ensure proper installation safety.

Understanding NEC Safety Guidelines for Box Extenders

The National Electrical Code (NEC) sets clear limits to ensure electrical box extenders don’t compromise safety. The code generally allows a maximum of two extension rings per box unless the manufacturer specifies otherwise. This limit preserves the box’s structural integrity and avoids weakening that could expose or damage wiring.

When you add extenders, you must recalculate the total box volume according to NEC guidelines. Overfilled boxes can cause overheating, create fire risks, and lead to code violations. The NEC provides tables for volume calculations based on wire gauge, conductor count, and devices within the box.

Using the proper materials is essential. Metal extenders must pair with metal boxes and plastic extenders with plastic boxes. Always follow manufacturer and NEC specifications to maintain compliance and prevent hazards.

Best Practices for Safe Installation of Box Extenders

Match extender materials carefully—metal with metal or plastic with plastic—and only use extenders listed for use with your specific box type. Using non-listed extenders can void approvals and create unsafe conditions.

Secure the extender firmly with screws designed for electrical boxes. Proper fastening avoids damage to both the extender and the wiring inside and ensures the assembly remains stable over time.

Before installation, disconnect power to the circuit. This step is non-negotiable to prevent electrical shock. Also, maintain proper grounding by using correctly sized grounding wires to provide fault current paths and help protect against shorts and electrical faults.

How to Use a Diamond Blade Grinder for Precision Internal Notches

Use a correctly sized diamond blade aligned with the grinder’s rotation, apply steady feed rates, and maintain controlled cutting speeds to achieve clean, accurate internal notches without damaging the stone.

Principles of Precision Internal Notching with Diamond Blade Grinders

Diamond blades cut by exposed diamond particles embedded in the blade matrix, which efficiently remove material while maintaining performance. Aligning the blade correctly to match the grinder’s rotation is essential for clean cuts and avoiding damage. Consistent cutting speeds and controlled feed rates help optimize cut quality, extend blade life, and prevent stressing the stone.

Selecting and Setting Up the Right Diamond Blade for Internal Notching

- Choose a blade diameter compatible with your grinder’s RPM according to manufacturer guidelines. This prevents overheating and preserves precision.

- Before mounting, align the blade’s directional arrow with the grinder’s rotation direction to ensure correct cutting action and avoid blade damage.

- Secure the blade with balanced pressure using the supplied wrench. Avoid over-tightening to protect both the blade and the tool’s spindle.

Can You Achieve a “Recessed Look” for Modern Luxury Outlets

Recessed luxury outlets are common in high-end designs, offering a flush, integrated appearance that blends with wall surfaces.

| Design Approach | وصف | ملحوظات |

|---|---|---|

| Flush-mount Installation Systems | Outlets embed directly into walls or surfaces, sitting level with surrounding materials. | Brands like Trufig offer systems compatible with faux and custom finishes, priced $100+ per outlet. |

| Customized Finishes and Colors | Finishes such as unlacquered brass, verdigris, brushed nickel, dark bronze, and taupe help outlets blend in. | Used to match walls, cabinetry, or backsplashes, reducing visual disruption. |

| Specialty Faceplates | Custom and faux-finish faceplates integrate outlets into overall design schemes. | These faceplates create the most elegant and refined appearance. |

| Modern Innovations | Includes smart tech features, integrated USB-A and USB-C ports, and flip-up grommets closing flush to surfaces. | Combines function with a clean, recessed look. |

Why Recessed Outlets Matter in Luxury Design

Recessed outlets remove the usual outlet protrusion, reducing clutter on natural stone or high-end walls. This matches the clean aesthetics demanded in premium architecture and interior design.

تعقيد التثبيت

Installing recessed outlets in thick natural stone or veneer walls requires precise measurement and special mounting techniques. Cutouts must be exact to avoid damage or visible gaps, which necessitates skilled workmanship and often adds cost. These challenges explain the premium pricing on flush-mount systems.

Material and Finish Matching

Matching outlet finishes to wall surfaces is crucial. Luxury projects often avoid standard white or ivory colors, opting instead for metal tones or custom finishes that complement stone textures and colors to maintain design consistency.

Smart Integration

Contemporary recessed outlets can incorporate smart home features, like remote control and power monitoring, without compromising the flush look. This integration supports modern user demands for convenience alongside style.

How to Smooth and Hone Raw Cut Edges for a Factory Finish

Use mechanical and abrasive processes like tumbling, vibratory finishing, and CNC diamond-blade cutting to remove burrs and achieve consistent, precise edges matching factory standards.

Key Concepts in Edge Smoothing and Honing

Raw cut edges of الألواح الحجرية الطبيعية need post-processing to meet factory finish quality. Mass-finishing methods such as centrifugal barrel deburring and vibratory finishing effectively smooth surfaces and remove burrs. Edge conditioning is crucial to reduce sharpness, improving safety during handling and installation.

- Mass-finishing processes like centrifugal barrel deburring operate much faster than vibratory finishing, completing work in a fraction of the time.

- Edge conditioning prevents sharp edges that could cause injury or material damage in later handling.

- Managing burr thickness is key: Burrs under 1.27µm require only light tumbling; burrs under 25.4µm can be handled with barrel or vibratory methods.

- Maintaining cutting tool quality by replacing tools every 2000–2500 meters and renewing sandpaper every 600 boards ensures uniform edge finishes.

- Advanced techniques such as abrasive flow machining and mechanized edge profiling improve precision on complex edges and help maintain tight tolerances.

Following these practices maintains quality and safety while streamlining production. Precise edge finishing also facilitates assembly, reduces wear on components, and extends product lifespan.

CNC Diamond-Blade Precision for Factory Edge Finishing

Top Source Stone uses CNC diamond-blade cutting to produce clean, consistent edges with tight tolerances on interlocking natural ألواح حجرية مكدسة. This precision is essential for the distinctive Z-Shape and S-Shape panels that incorporate a “ذكر أنثى” interlocking system.

- CNC diamond blades deliver sharp, clean cuts that ensure panels fit tightly to mask joints and substrate, producing a seamless architectural finish.

- Precise edge finishes align with the company’s mantra: “Premium Nature, Engineered for Architecture.”

- This method reduces the need for excessive sanding or deburring after cutting, speeding up production and lowering labor costs.

- Edges finished this way meet industry durability standards, maintaining resistance to UV exposure and environmental conditions typical in key markets like the Gulf region.

The CNC diamond-blade precision process ensures consistent, professional results that enhance both the visual appeal and functional performance of natural stacked stone installations.

Avoiding the “Small Piece” Trap: Planning Your Layout Carefully

Careful layout planning ensures natural الألواح الحجرية fit well together without leaving small leftover pieces that disrupt the wall’s appearance and complicate installation.

Understanding the Impact of Small Pieces in Stone Layouts

Small leftover pieces interfere with the visual flow of natural stacked stone walls by creating irregular joints and uneven textures. These inconsistencies distract from the stone’s natural beauty and compromise the overall aesthetic.

Installers face higher complexity and longer labor times when fitting small pieces. Additional cuts and adjustments are often necessary, slowing down the process and increasing risk of errors.

Pieces that are too small tend to break more easily. This vulnerability reduces the wall’s structural integrity and durability over time, potentially leading to costly repairs or replacements.

Optimizing Layout Using Interlocking Panel Designs

Top Source Stone’s interlocking Z-Shape and S-Shape panels feature precise male-female edges. This design enables tight, seamless connections that hide vertical joints and prevent the need for small filler pieces.

- The precision CNC diamond-blade cutting process achieves consistent panel sizes. This uniformity significantly reduces waste and the creation of small offcut pieces during installation.

- Matching L-Corners simplify perimeter layouts. These corners are pre-fabricated to fit perfectly with the interlocking panels, eliminating custom cuts that often produce small and awkward pieces.

By combining interlocking panels with corner solutions, installers achieve a clean, natural look with fewer cuts and no need to force-fit tiny pieces, preserving both aesthetics and structural strength.

الأسئلة المتداولة

How to Cut an Outlet Hole in 1-Inch Thick Natural Stone?

Use a wet saw or angle grinder with a diamond cutting blade sized around 3⅜\” for precision. Mark the outlet opening carefully, score shallow grooves on the stone surface to prevent chipping, and cut slowly from both sides. Finish the edges with diamond grinding cups for a smooth surface. Always ensure dust suppression and wear proper safety gear.

Are Electrical Box Extenders Needed for Stone Veneer Installations?

Electrical box extenders are necessary when adding القشرة الحجرية thickness so outlets and switches sit flush with the new surface, preventing gaps around cover plates. For bare stone walls without added material, extenders usually aren’t required, but you must secure electrical boxes properly using masonry anchors.

How to Fix a Stone Panel Cut Too Wide for the Outlet Plate?

The most practical fix is to attach a shim or spacer piece to the back of the لوحة حجرية to reduce its effective width. For minor oversizing, carefully trimming edges with diamond cutting tools like a Dremel can help. Maintain proper spacing of about 1/4 inch between panels for expansion.

Can You Use a Jigsaw with Diamond Blades for Cutting Stone Outlets?

Diamond blades are designed for specific cutting tools and materials. The available information does not confirm compatibility of diamond blades with jigsaws. Consult your jigsaw and blade manufacturer’s specifications before use to ensure safety and performance.

How to Hide Gaps Around the Outlet Cover in Stone Walls?

Replacing the outlet’s wall plate with a larger jumbo plate that extends beyond the outlet edges effectively covers gaps and imperfections. For recessed outlets, a box extension can bring the outlet forward, allowing the jumbo plate to fit properly and eliminate visible gaps.

الأفكار النهائية

While cheaper stone options might reduce initial costs, only Top Source Stone’s CNC diamond-blade precision and same-batch quarry consistency guarantee the seamless fit and durability that protect your reputation from costly callbacks and aesthetic compromises. Investing in premium natural stacked stone means fewer installation challenges, no structural weaknesses, and long-term trust from your clients. Quality inventory shields your margins and brand in a competitive market demanding flawless results.

Don’t leave quality to chance—start with a sample kit to experience our precise panel fitment and finish. Reach out to our engineering team to explore private label options or discuss project-specific requirements tailored to your business. Secure your advantage with Top Source Stone’s direct quarry source solutions today.