アウトドアキッチン & BBQ projects are the front line between design intent and costly warranty claims, extended rework hours, and potential safety noncompliance. In practice, natural stone on BBQ islands fails when adhesion, thermal planning, and detailing fall short of contractor tolerances—turning small specification gaps into callbacks, lost margin, and damaged client relationships. Owners expect durable finishes; installers work on tight schedules and must manage heat, grease, UV exposure, and structural limits that together raise the stakes for every adhesive and joint detail.

This guide serves as a technical SOP for natural stone BBQ island installation: it sets the adhesion standards that form the core of long-term performance, then covers heat-proximity safety, professional pre-sealing to prevent grease staining, UV-resistant stone selection, toe-kick and countertop overhang detailing, methods for mounting stone over stainless steel frames, the critical 1/8″ expansion gap around grills, and when to reinforce the patio slab. Each section ties back to adhesion and includes contractor-ready checks, specification notes, and field test points you can use on bids, shop drawings, and site inspections.

Why Outdoor Kitchens Demand the Highest Adhesion Standards?

Outdoor kitchens fail at joints and cutouts unless you use flexible bonds, engineered supports, and site-verified adhesives.

Evaluate thermal loads and design movement joints

Map every heat source and quantify expected temperature swings before you detail joints. Direct sunlight, grill/barbecue radiant heat and diurnal surface changes produce the largest strains; design movement joints to accommodate those cycles rather than rely on rigid adhesion. Leave a continuous perimeter of movement joints and isolate heat-producing equipment so expansion concentrates in planned gaps, not at bonded interfaces.

- Expected heat sources: direct sun, grill radiant heat, and diurnal swings — document worst-case surface temperature rise near grills for joint sizing.

- Worktop-to-equipment clearance: maintain at least 3/16″ (≈5 mm) between worktop edges and metal or heat-producing equipment; seal that gap with heat-resistant silicone.

- Panel-to-adjacent-structure sealant joint: minimum 1/8″ (≈3 mm) to prevent water ingress and allow differential movement.

Select adhesives and sealants: specifications and application limits

Specify flexible, exterior-grade polyurethane adhesives that list thermal cycling performance and remain elastic across the expected temperature range. Avoid cement-based and rigid epoxy adhesives for horizontal worktops near grills; their low elongation creates brittle failure zones when stone and substrate expand at different rates. For visible joints, use heat-resistant silicone and match color where appearance matters.

- Adhesive choice: flexible polyurethane rated for exterior use and thermal cycling; confirm compatibility with slate, quartzite, sandstone, granite and marble.

- Sealant: heat-resistant silicone for exposed joints; use colored silicone where finish match is required.

- Application limits: follow manufacturer limits for substrate temperature, humidity, open time and cure time; collect technical data sheets (TDS) on site.

- Verification: require mock-up adhesion tests or TDS proof that the bond-line provides the necessary movement capacity under expected temperatures.

Design structural supports for cutouts and point loads

Treat every cutout and overhang as a structural detail. Provide continuous support under sink and barbecue openings and design framing to transfer loads away from panel edges and stress concentrations. Where thermal isolation reduces the bonded area, add mechanical fixings or brackets but allow movement so fasteners do not induce point stresses that crack stone.

- Load calculations: use panel dead load ~30–40 kg/m² (8–12 lbs/ft²) for standard flat panels; use ~55 kg/m² for rough panels when sizing supports.

- Panel thickness: specify 1.0–2.5 cm standard; select up to 3.5 cm for heavy-duty, cantilevered or high-traffic installations.

- Fastening: choose brackets and anchors that allow axial and lateral slip; secure the frame so the stone carries compressive loads while fixings limit separation only.

- Backing and bond pattern: detail backing materials and adhesive bead/trowel patterns to distribute loads and reduce point bending at openings.

Surface preparation, panel handling, and installation sequence

Start with same-batch quarry material for visible runs to avoid color mismatch and reduce rework. Clean and dry both substrate and stone mating surfaces: remove dust, grease and loose particles immediately before adhesive application. Dry-fit interlocking Z/S-shape panels and L-corners to confirm alignment and fit; adjust substrate framing where required before final bonding.

- Handling: store panels flat and protected; avoid edge impacts that create micro-cracks.

- Adhesive application: apply beads or trowel pattern per manufacturer and maintain recommended bead thickness to preserve bond-line flexibility.

- Installation sequence: allow full cure in load-bearing zones before cutting openings or applying point loads; complete mock-ups first when using new adhesive systems.

Verification tests and ongoing inspection protocols

Validate performance on site with representative mock-ups. Perform pull-off or peel tests to confirm adhesion under the project’s specific thermal and moisture conditions, and run thermal cycling plus water infiltration tests on the mock-up before you install production panels. Inspect seals and bonded joints after initial cure and at scheduled intervals to catch adhesion loss, cracking or water penetration early.

- Testing: run pull-off tests and thermal cycles on mock-ups; document results against acceptance criteria.

- Inspection schedule: inspect after initial cure, then quarterly for the first year and annually thereafter, or increase frequency in freeze-thaw or high-salinity environments.

- Record-keeping: log adhesive batch numbers, environmental conditions during installation, and cure times for warranty and troubleshooting.

- Maintenance: prescribe sealant replacement intervals and cleaning procedures for UV exposure, salt spray and freeze-thaw climates, and confirm product UV and freeze-thaw ratings before specifying for coastal or cold regions.

Managing Intense Heat Proximity: Is Stone Safe Near Commercial Grills?

自然の積み石 performs near commercial grills when you match material, allow thermal gaps, use flexible adhesives, and provide heat-rated substrates.

Material heat tolerance and panel behaviour for natural stacked stone

トップソース Stone natural stacked stone (slate, quartzite, sandstone, granite, marble) tolerates high surface temperatures, but it moves. Use the published panel formats — 150 x 600 mm or 150 x 550 mm — with standard thicknesses from 10–25 mm and premium/rough panels up to 35 mm. Expect flat panels to weigh about 30–40 kg/m² (8–12 lb/ft²) and rough panels around 55 kg/m²; plan substrate and fixings for those loads.

- Choose quartzite or granite where sustained radiant heat and UV stability matter; slate and sandstone work for lower-exposure areas.

- Design for differential movement between stone, adhesive, and backing to avoid localized stress at cutouts or corners.

- Use interlocking Z/S panels or matching L-corners to reduce visible seams and improve mechanical continuity at heated transitions.

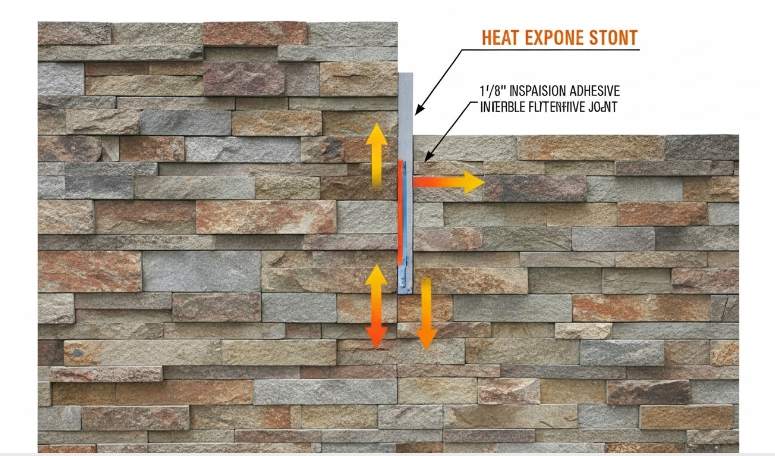

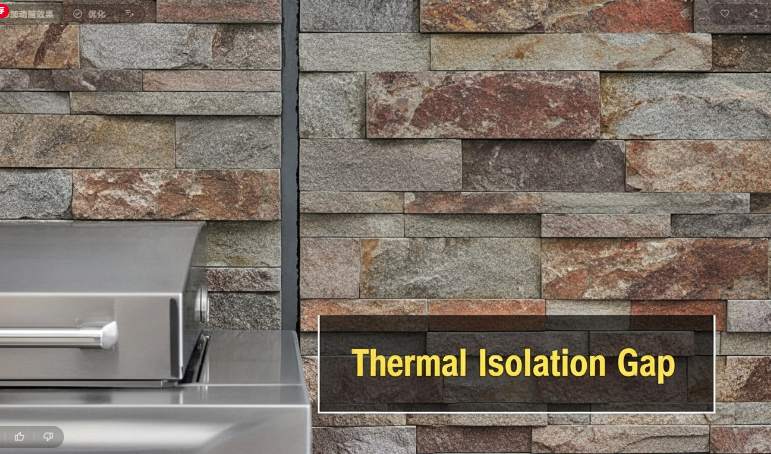

Clearance, thermal isolation and joint detailing next to commercial grills

Maintain intentional thermal isolation between the stone and heat-producing metal. Leave at least 3/16 in (≈4.8–5 mm) clear between stone surfaces or worktops and any direct grill structure or metal that will expand. Seal visible joints with a minimum 1/8 in (≈3.2 mm) width using a heat-resistant silicone rated for high-temperature exposure (typical products rate 200–300°C).

- Where grills produce sustained radiant heat, insert an air gap or non-combustible thermal barrier behind the veneer to protect the substrate and slow heat transfer.

- Keep underside and airflow gaps specified by the appliance manufacturer; never cover ventilation openings that moderate grill heat.

- Use interlocking Z/S panels or pre-fabricated L-corners at edges to concentrate load paths away from exposed heated seams and simplify sealing details.

Adhesives, substrates and mechanical support for high-heat installations

Specify flexible bonding systems and heat-rated substrates. Prefer flexible polyurethane adhesives for exterior and high-heat conditions; avoid rigid cement-based mortars and standard epoxies that crack under thermal cycling. Mount stone to a non-combustible, heat-resistant backer such as cement board and provide continuous mechanical anchorage where loads concentrate.

- Use stainless-steel anchors and fasteners for mechanical fixings; add supplemental brackets beneath heavy grill mounts, cutouts, and countertop openings.

- Reinforce cutout perimeters and sink/grill interfaces with structural backing to distribute stress and prevent point failure.

- Mock up a representative assembly and test adhesion plus sealant compatibility under expected radiant and convective heat before full installation.

- Follow grill manufacturer clearances and local code for required gaps, venting, and load limits; adjust stone detailing to meet those constraints.

Premium Natural Stone, Faster Installs

How to prevent grease stains: the science of professional pre-sealing

Stop grease before it bonds: apply professional protective treatments to fabrics and seal porous stone surfaces to block oil penetration. Oil binds to fibers and stone pores at a molecular level, so pre-treatment creates a repellant barrier that reduces stain adhesion and makes cleanup mechanical rather than chemical.

Use physical barriers under cooking surfaces—under-grill splatter mats (typical size 43.5″ × 30.5″) and silicone griddle covers—to catch drip and embers. For accidental contact, start with mild cleaning (Dawn dish soap + OxiClean paste), use absorbents (kitty litter or sawdust) for fresher oil, and reserve aggressive chemicals (muriatic acid) for trained professionals with PPE.

Why UV-Proof Natural Stone Won’t Fade on Your BBQ Island in 20 Years?

Select quarry-matched quartzite or slate and design for thermal movement to keep stone color and integrity stable for two decades.

Material selection and same-batch sourcing for 20-year color stability

Choose 100% natural stone—quartzite, slate, sandstone, granite or marble—because these minerals carry inherent UV stability and will not undergo resin-driven fading like engineered quartz. For large runs, source from the same quarry vein to hold hue uniformity; トップソースストーン reports roughly 95% color consistency within a single batch, which prevents patchy appearances on long BBQ islands.

Specify panel geometry and mass up front to simplify joint layout and structural design. Use the standard rectangle panel formats (6″ ×24″ / 150 x 600 mm or 6″ ×22″ / 150 x 550 mm) for predictable vertical alignment. Standard thickness ranges 1.0–2.5 cm; specify up to 3.5 cm for exposed edges or heavy-use islands. Plan substructure loads for approximately 30–40 kg/m² for flat panels and ~55 kg/m² for rough-stack panels and confirm slab or frame capacity before ordering.

- Materials: Quartzite, Slate, Sandstone, Granite, Marble (100% 天然石))

- Same-batch quarry consistency: ~95% hue uniformity per order

- Panel formats: 6″ ×24″ (150 x 600 mm) or 6″ ×22″ (150 x 550 mm)

- Thickness: 1.0–2.5 cm standard; up to 3.5 cm for heavy-use edges

- Weight to plan for: ~30–40 kg/m² (flat) or ~55 kg/m² (rough)

Installation tolerances, joint sealing and adhesive strategy for thermal exposure

Bond using flexible polyurethane adhesives and avoid rigid cement-based mortars or epoxies that crack under thermal cycling. Maintain thermal isolation gaps where stone meets metal or direct heat: keep at least 3/16″ (~5 mm) clearance between the worktop/stone and BBQ metal or other heat sources and seal that gap with heat-resistant colored silicone to allow expansion while preventing water entry.

Specify movement joints no narrower than 1/8″ (~3 mm) and seal them with high-temperature silicone rated for outdoor UV exposure. Use interlocking Z-shape or S-shape panel formats with CNC diamond-blade precision edges to reduce visible vertical joints and improve long-term joint stability. Always provide continuous structural support at cutouts and around sinks or barbecue openings, and reinforce concentrated-load zones to eliminate stress risers. For coastal or Gulf installations, use corrosion-resistant anchors and compatible, salt-spray-rated sealants to protect fastenings and adhesive bonds.

- Adhesive: Flexible polyurethane (avoid rigid cement-based or epoxy adhesives)

- Thermal isolation: ≥3/16″ (~5 mm) gap to BBQ metal, sealed with heat-resistant colored silicone

- Movement joints: ≥1/8″ (~3 mm) sealed with heat-resistant silicone

- Joint strategy: Interlocking Z/S panels + CNC diamond-cut edges for concealed vertical joints

- Coastal best practice: corrosion-resistant anchors and salt-rated sealants

Structural backing, load planning and maintenance to preserve finish for 20 years

Design the substructure to carry panel dead load plus live loads of appliances and users; size the support for up to ~55 kg/m² when using rough panels. Use matching L-corners and full-coverage panels to reduce exposed edges and avoid weathering lines where materials transition. Provide lintels or continuous backing at appliance openings and verify that cutouts sit on supported spans to prevent cracking at stress points.

Set an inspection and maintenance routine: visually inspect joints, silicone seals and mechanical anchors annually and reseal or tighten as needed. Clean stone with a pH-neutral detergent and low-pressure rinse; avoid strong acids and abrasive cleaners that degrade the finish. If you apply a sealer, choose a breathable stone sealer and plan reapplication every 5–10 years based on exposure. Capture pre-shipment verification photos and on-site installation images to confirm same-batch appearance and correct joint details for warranty and quality control.

- Substructure design: size for dead + live load; plan for up to ~55 kg/m²

- Edge protection: matching L-corners and full-coverage panels to reduce weathering

- Inspection: annual visual check of joints, silicone seals and anchors

- Cleaning: pH-neutral detergent, low-pressure rinse; avoid acids and abrasives

- Sealer policy: breathable sealer only; reapply every 5–10 years as exposure dictates

- Verification: pre-shipment photos/videos and on-site documentation to confirm same-batch match and joint workmanship

How to Design Toe-Kicks and Countertop Overhangs with Rugged Stone Panels?

Correct support, panel choice and flexible sealing prevent structural failure and reduce lifetime repair costs on outdoor kitchen islands.

Structural support and load distribution for toe-kicks and overhangs

Select panel thickness to match the load: use standard 1.0–2.5 cm panels for vertical cladding and plan for up to 3.5 cm (rough/premium) where you cantilever or expect high stress. Account for panel mass when sizing your subframe and fasteners — flat panels weigh roughly 30–40 kg/m² while rough-texture panels approach 55 kg/m². Where you cut for sinks, grills or service access, carry loads into the framing by providing continuous substrate or reinforced blocking under those cutouts so the stone transfers stress to structure, not adhesive.

Place mechanical supports across the full width of any overhang instead of relying on adhesive alone, and combine those supports with flexible adhesive bonding to absorb thermal cycling. Always add local blocking or brackets beneath aperture edges and specify support at every corner and junction to prevent concentrated bending and cracking at exposed returns.

- Pick thickness by use: 1.0–2.5 cm for cladding; up to 3.5 cm for cantilevers and heavy overhangs.

- Design subframe and fasteners for panel weight: 30–40 kg/m² (flat), ~55 kg/m² (rough).

- Provide continuous substrate or reinforced framing under cutouts and openings.

- Use mechanical supports across overhang width and add blocking at corners and junctions.

Panel selection, edge configuration and modular detailing

Standardize on rectangular formats for linear runs — 150×600 mm (6×24 in) or 150×550 mm (6×22 in) — to keep coursing consistent and speed installation. For overhang returns and visible edges, choose interlocking Z-shape or S-shape panels with CNC diamond-blade precision so male–female joints hide vertical seams and deliver the seamless technology Top Source Stone engineers for tight returns.

Match pre-fabricated L-corners for all 90° transitions and toe-kick returns to maintain texture and color continuity; specify same-batch quarry sourcing to preserve about 95% hue uniformity across contiguous runs. Select surface finish by application: use natural cleft or split-face for rugged exposed faces and a seamless finish where tight toe-kick junctions demand minimal shadow lines.

- Panel formats: 150×600 mm or 150×550 mm for linear, modular runs.

- Edge types: Z-shape / S-shape interlocks with CNC diamond-blade precision to conceal vertical joints.

- Transitions: matching L-corners for 90° wraps and toe-kicks to keep texture continuity.

- Batch control: source from the same quarry vein to achieve ~95% hue uniformity.

Adhesive, sealing and thermal-isolation practices for outdoor kitchen conditions

Use flexible polyurethane adhesives for exterior stone installations and avoid rigid cement-based or epoxy systems that crack under thermal cycling. Dimension joints and isolation gaps to manage moisture and heat: seal vertical and horizontal joints at least 1/8″ wide with heat-resistant silicone and maintain minimum 3/16″ isolation gaps between worktops and adjacent heat sources or metal to prevent heat transfer and buckling.

Specify color-matched, heat- and UV-resistant silicone at appliance interfaces and where stone meets metal; require adhesive plus mechanical fastening wherever possible and design for movement by leaving isolation gaps and using flexible sealants. Verify installation performance by dry-fitting インターロックパネル, confirming full substrate coverage behind stone, and inspecting bond lines and sealant depth before final closure.

- Adhesive: specify flexible polyurethane; do not use rigid cement or epoxy on exterior grills or islands.

- シール & gap sizes: joints ≥1/8″ sealed with heat-resistant silicone; maintain ≥3/16″ clearance to heat sources/metal.

- Sealant spec: color-match and require UV, humidity and salinity resistance for coastal or Gulf installations.

- Combine adhesive bonding with mechanical fastening and plan thermal movement with isolation gaps.

- Verification steps: dry-fit panels, confirm concealed substrate coverage, inspect bond lines and sealant depth before final closure.

Can You Install Natural Stone Over a Stainless Steel Island Frame?

Natural stacked stone performs on stainless steel islands when designers provide clear load paths, flexible adhesives, thermal movement joints, and continuous backing at cutouts.

Assess structural capacity and load distribution of the stainless steel island frame

Start by sizing the frame for the stone dead load: flat-profile 積み上げられた石 weighs about 30–40 kg/m² (8–12 lbs/sq.ft), and rough/oversized profiles approach 55 kg/m². Use standard panel dimensions (150 × 600 mm or 150 × 550 mm) and thickness bands (10–25 mm typical, up to 35 mm premium) to calculate distributed loads and reactions rather than treating pieces as point loads.

Design the frame so unsupported spans under the veneer do not exceed 300 mm (12″) or provide continuous bearing to eliminate point-loading. Reinforce zones around sink and barbecue cutouts with continuous support members or steel brackets and add a rigid intermediate substrate—cement backer or marine-grade exterior plywood with a vapor barrier—to spread loads and deliver a uniform fastening plane. Confirm stainless grade and weld quality so the frame resists permanent deformation under combined dead load and expected live loads (equipment, users, service access).

Choose adhesives and mechanical fastenings for exterior stone-on-metal installation

Select an exterior-grade polyurethane adhesive that retains flexibility at high temperatures and during thermal cycling; avoid rigid cement-based adhesives and epoxies where the stone will see direct sun or grill heat. Apply adhesive for full contact where possible using continuous beads or fillets sized per the adhesive manufacturer—target a bondline in the 3–5 mm range—and respect cure-time and ambient temperature limits during installation.

Use stainless-steel mechanical anchors or screws in the same corrosion class as the frame and fit neoprene or EPDM washers to isolate the stone from metal. Space fasteners by panel size and local loads—typical spacing falls between 150–300 mm. For interlocking Z-Shape or S-Shape panels, rely on male/female engagement to reduce vertical screw count and use CNC-fitted edges to minimize gaps. Pre-fabricated L-corners and matched corner panels reduce field cutting and stress at 90° transitions. Pre-drill stone where required, torque fasteners to a controlled value to avoid cracking, and use non-metallic shims or adhesive pads to prevent direct metal-to-stone contact.

- Adhesive: exterior polyurethane; bondline 3–5 mm.

- Fasteners: stainless-steel anchors with neoprene/EPDM washers; spacing 150–300 mm.

- Panels: 150×600 mm or 150×550 mm; thickness 10–25 mm (standard), up to 35 mm (premium).

Detail joint treatment, thermal movement allowance, and water-management measures

Leave thermal isolation gaps where stone adjoins heat sources or adjacent metalwork: a minimum 3/16″ (≈4.5 mm) gap and a high-temperature silicone seal will reduce heat transfer and allow movement. Seal horizontal and vertical stone joints at least 1/8″ (≈3 mm) with exterior-grade, heat-resistant silicone; insert a backer rod in wider gaps to control sealant depth and bonding geometry. Provide perimeter movement joints where stone meets cabinetry, appliances, or tertiary elements so thermal expansion and contraction do not force stresses into the veneer or anchor system.

Install a non-absorbent backing layer and create ventilation or drainage paths behind the 石 to prevent trapped moisture against the stainless frame. Specify stone grades with proven UV stability and high salinity/humidity resistance for coastal or high-salt environments. Complete the work with a verification sweep: confirm joint widths, check sealant adhesion and depth, verify panel alignment, and inspect anchorage points for correct corrosion protection and positive load transfer.

- Thermal gap: ≥3/16″ (≈4.5 mm) to heat sources; seal with heat-resistant silicone.

- Joint width: ≥1/8″ (≈3 mm); use backer rod for wider gaps.

- Moisture control: non-absorbent backing plus ventilation/drainage behind veneer.

- Final checks: joint dimensions, seal adhesion, anchor corrosion protection, and load path verification.

Dealing with Expansion: Why a 1/8″ Gap Around the Grill is Critical?

A controlled 1/8″ clearance prevents thermal stress damage to 積み上げられた石 and preserves sealant and adhesive performance around hot appliances.

Calculate thermal movement using ΔL = α · L · ΔT to validate a 1/8″ clearance

Use ΔL = α × L × ΔT and keep units consistent: convert L to meters when α is in /°C, then report ΔL in millimetres or inches. 自然の積み石 (slate, quartzite, granite) typically shows α in the 4–10 ×10⁻⁶ /°C range; pick a conservative design value (for example 8 ×10⁻⁶ /°C) to cover quarry variability and worst-case cycles.

Example: a 24 in (0.6 m) panel with ΔT = 60°C and α = 8×10⁻⁶ /°C gives ΔL = 8e-6 × 0.6 × 60 = 0.000288 m → 0.288 mm (~0.011 in). A 1/8 in (3.175 mm) gap therefore provides roughly a 10× margin plus room for sealant movement and tooling tolerances. If panel length (L) or expected ΔT increases, scale the gap proportionally or adopt the appliance-specified clearance when that value exceeds 1/8″. For very long runs or localized grill temperatures above the assumed ΔT, increase the clearance and re-run ΔL calculations using the panel dimensions (standard Top Source Stone rectangle panels are 6″ × 24″ / 150×600 mm) and the conservative α value.

Specify joint filler and adhesives: heat-rated sealant, backer rod, and flexible bonding

Seal the 1/8″ gap with a heat-resistant, UV-stable neutral-cure silicone formulated for outdoor grill exposure. Select a non-sag, neutral-cure silicone rated for continuous service at least 200°C (392°F) so the sealant retains elasticity under repeated heating cycles and sun exposure. For color-critical installations, pick a sealant shade that matches the stone finish to keep the aesthetic seamless。

Bond stone panels using flexible polyurethane adhesives designed for thermal cycling; they absorb movement and prevent brittle failures that cement-based mortars or rigid epoxies produce near heat sources. Place a closed-cell polyethylene backer rod sized to leave sealant depth at roughly half the joint width (for a 1/8″ gap, target ~1/16″ sealant depth) to control joint movement and avoid three-sided adhesion. Tool the sealant so it contacts only the stone faces; this forces movement into compression/extension of the sealant and prevents adhesion to the backer rod.

On-site controls and verification checklist for installing a 1/8″ gap around grills

- Mock-up and thermal cycle: install representative stacked-stone panels and the actual grill model, heat to operating temperature, and confirm the 1/8″ gap and chosen sealant accommodate thermal movement without cracking, smoke staining, or adhesion loss.

- Mechanical isolation: install thermal isolation clips or non-compressible spacers between stone and metal to reduce direct heat transfer and prevent differential movement stress; isolate vertical seams from appliance frames where possible.

- Follow appliance clearances: check the grill manufacturer’s required clearances; if the appliance specifies a larger gap (for example 3/16″), use that value instead of 1/8″. Document that you verified those requirements on-site.

- Inspect and document: check sealant adhesion and panel edges after 24–72 hours and again after initial heat cycles; photograph any shrinkage, delamination, or loss of adhesion and log observations in the project quality file.

- Traceability record: record adhesive and sealant product names, batch numbers, suppliers, application and cure times, and link these records to the stone batch (same-batch quarry consistency) for warranty and service traceability.

Managing Structural Load: Does Your Patio Slab Need Reinforcement?

Assess slab capacity early: 積み上げられた石 can add roughly 6–11.3 psf (use a +20% contingency) and trigger costly reinforcement if ignored.

Calculate dead load from natural stacked stone panels

Start with the manufacturer’s mass data and panel geometry: standard Top ソースストーンパネル measure 150×600 mm or 150×550 mm with thickness typically 1.0–2.5 cm and up to 3.5 cm for premium pieces. Use the published mass ranges: flat panels ≈ 30–40 kg/m² (8–12 lbs/sq.ft) and rough panels ≈ 55 kg/m². Apply a contingency allowance for mortar, adhesives, backer boards and fixings—typical practice: +20%—before you convert to psf for structural checks.

- Convert area loads: 30–40 kg/m² → 6.1–8.2 psf; 55 kg/m² → 11.3 psf. With +20% contingency these become ~36–48 kg/m² → 7.4–9.8 psf and ~66 kg/m² → 13.6 psf.

- Compute linear loads for benches or short walls: multiply the area load (kg/m²) by the stone-covered width (m) to get kg per linear metre. Example: contingency flat panel 36 kg/m² × 0.6 m wide = 21.6 kg/m per linear metre (≈14.5 lb/ft).

- Logistics to structure: account for box coverage (standard boxes cover 0.63–0.72 m²) when estimating total added dead load per pallet or crate for transport and handling checks.

Assess patio slab condition and triggers that require reinforcement

Perform a targeted slab inspection before you commit to 石のクラッディング. Use visual and simple load checks to identify ongoing cracks, active settlement, visible deflection under load, or repairs that reopen after loading. Treat slabs thinner than typical residential practice (4–6 in) or slabs on poor soils as higher risk when you add heavy veneer that raises dead load by up to ~13.6 psf with contingency.

- Signs that demand action: hairline cracks that propagate, uneven settlement, deflection under a known load, and recurring repair lines.

- Capacity check: sum existing dead load + added stone dead load + expected live loads. If slab capacity or safety margin is unknown, engage a structural engineer to verify or run calculations.

- If analysis shows the slab cannot carry combined loads with an appropriate safety factor, plan reinforcement before installation to avoid rework and liability.

Select reinforcement and attachment methods compatible with stacked stone cladding

Choose reinforcement that routes load paths to soil or structural beams rather than concentrating loads on thin concrete. Viable reinforcement strategies include bonded structural toppings with fiber or rebar, added edge or turned-down beams, underpinning footings, and localized mechanical supports that transfer load off the slab. For any option, coordinate the structural detail with the stone supplier so panel type, weight and L-corner usage match the engineering solution.

- Bonded overlays: follow mechanical-prep steps—clean the slab, profile (grind or shot-blast) to achieve a key, apply a bonding agent—and place the engineer-specified overlay thickness and reinforcement (fiber or mesh; or top-layer rebar). Specify overlay thickness and reinforcement layout in the engineer’s drawing.

- Mechanical attachment: specify corrosion-resistant anchors (316 stainless or equal), distribute anchors to avoid point loads, and use interlocking Z/S panels and matching L-corners to spread shear and reduce concentrated stress at edges and transitions.

- Site coordination: confirm same-batch quarry consistency with the supplier, order matching L-corners for transitions, and factor box coverage (0.63–0.72 m² per box) and pallet loads into handling and temporary support planning to prevent local overloading during installation.

- When in doubt, specify a structural engineer to size turned-down beams or underpinning. Use reinforcement spacing rules as a guide (keep reinforcement grid spacing generally ≤ 2× slab thickness) and place the top-layer reinforcement where it will limit cracking and control deflection.

結論

Proper natural stone installation on commercial BBQ islands protects users and equipment, meets OSHA and local building standards, and prevents costly callbacks. Prioritizing adhesion, heat management, and structural reinforcement extends warranty coverage and reduces long-term maintenance.

Start by auditing your current project setups for adhesion, grill clearances, and slab capacity, or contact トップソースストーン for certified samples and a commercial catalog tailored to outdoor kitchens. Request same-batch color confirmation and pre-shipment visuals to protect margins and ensure on-site consistency.

よくある質問

Can you put natural stacked stone on a commercial BBQ island?

Yes — 自然の積み石 can be used on a commercial BBQ island provided it’s installed to outdoor-kitchen adhesion standards: use flexible polyurethane adhesives (not rigid cement-based or epoxy), allow thermal-isolation gaps (minimum 3/16″ ) between stone and barbecue/metal, seal joints (minimum 1/8″) with heat-resistant silicone, and ensure adequate support at openings and cutouts so stress points won’t cause cracking or separation.

Best natural stone for an outdoor kitchen in a hot climate?

Rather than a single “最高” stone, select a 天然石 with low thermal expansion, good dimensional stability in direct sunlight and heat, and low porosity so it resists moisture. Equally important is installation: use flexible polyurethane adhesives, leave thermal-isolation gaps (≥ 3/16″) from heat sources, and seal joints (≥ 1/8″) with heat-resistant silicone to accommodate temperature swings and moisture exposure.

How to protect stone from grease stains near the grill?

Protect stone by preventing infiltration and allowing movement: install joints at least 1/8″ wide sealed with heat-resistant silicone to block grease and moisture; maintain isolation gaps (≥ 3/16″) to limit direct heat transfer; use flexible polyurethane adhesives so bonds and seals remain intact under temperature cycles; and provide proper support at stress points to avoid cracks or gaps that trap grease.

Is stone veneer safe for outdoor fireplace/BBQ combos?

Stone veneer can be safe if installed to outdoor adhesion and thermal-isolation standards: avoid rigid adhesives (cement-based or epoxy), use polyurethane adhesives for flexibility, maintain gaps of at least 3/16″ to isolate heat sources, and seal joints (minimum 1/8″) with heat-resistant silicone. Also ensure adequate backing/support at stress points so thermal cycling won’t cause separation or cracking.

How to install stone around outdoor kitchen doors?

Allow for thermal movement and moisture control: leave gaps of at least 3/16″ between stone and door or metal frames, seal joints of at least 1/8″ with heat-resistant silicone, use flexible polyurethane adhesives for bonding, and provide sufficient support around cutouts and openings to distribute loads and avoid stress concentrations that lead to cracking or separation.