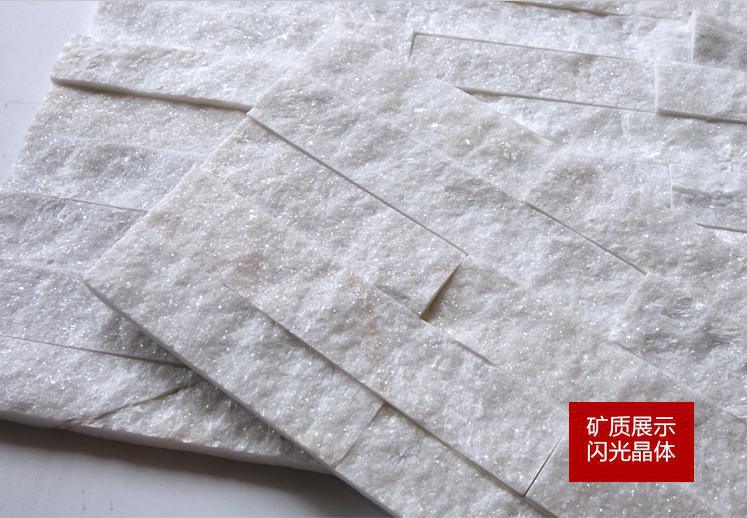

Standardizing a Professional Tool Kit across your crew is the most effective way to prevent margin erosion caused by stone fracture and on-site rework. Substandard equipment frequently damages 100% natural quartzite and slate panels, destroying the 95% hue uniformity expected in premium architectural projects.

We identify the specific hardware required to handle 40kg/m² panels and preserve the CNC-cut edges of Z-shape interlocking systems. This selection focuses on achieving 95% mortar coverage and meeting OSHA silica dust standards to protect both project durability and installer safety.

Essential Tools for Every Professional Natural Stone Mason

Snelle vergelijking

| Productnaam | Het beste voor | Belangrijkste kenmerk | Uitspraak |

|---|---|---|---|

Spattende hamer |

Ruwe stenen dressing | Hoge slagkracht voor het bewerken van zware stenen | Krachtig voor de initiële vorming, maar vereist een hoge fysieke kracht. |

Haakse slijper met diamantbladen |

Precisiesnijden op locatie | Draagbaar en zeer veelzijdig mechanisch snijden | Zeer veelzijdig voor de meeste taken op locatie, hoewel stofbeheer van cruciaal belang is. |

Professionele natzaag |

Spaanvrije precisiesneden | Watergekoelde stofverwijdering en schone randen | Ideaal voor projecten met grote volumes die perfect schone, professionele voegen vereisen. |

Metselaarsniveau (geestniveau) |

Structurele uitlijning | Robuuste duurzaamheid voor grote wandoppervlakken | Essentieel voor het behoud van professionele horizontale en verticale nauwkeurigheid. |

Draagbare mortelmixer |

Uniforme mortelconsistentie | Mechanisch mengen voor batchsterkte en kleureenheid | Bespaart arbeid en waarborgt de kwaliteit, mits deze na gebruik direct wordt gereinigd. |

Wig en veren |

Gecontroleerd steensplijten | Gecontroleerde druk voor natuursteen pauzes | De beste methode voor zuivere, natuurlijk ogende spleten op dikke stenen. |

Beitels met hardmetalen punten |

Detailafwerking | Geharde punten voor het trimmen van kwartsiet en graniet | Superieure duurzaamheid voor hard finetunen natuurstenen. |

Spattende hamer

Dit gereedschap levert de **ruwe slagkracht** die nodig is om massieve steengroeveblokken in werkbare vormen af te breken.

Een spatelhamer fungeert als het belangrijkste gereedschap voor het bewerken van ruwe stenen. De zware kop is ontworpen om grote stukken afvalmateriaal snel te breken en te verwijderen.

Dankzij het uitgebalanceerde ontwerp kunnen metselaars krachtige slagen uitdelen die volgen op de natuurlijk korrel van de steen, waardoor een efficiënte initiële vorming wordt gegarandeerd.

📊 In één oogopslag:

- 📍 Toepassingsgebied: steen Vormgeven

- 🏭 Kernsterkte: Ruwe stenen dressing

- 🌍 Belangrijkste markten: Globaal

Waarom we ervoor kozen:

| ✅ De overwinningen | ⚠️ Afwegingen |

|---|---|

|

|

Haakse slijper met diamantbladen

Hij fungeert als het **veelzijdige werkpaard** op de bouwplaats en kan alles aan, van snel trimmen tot nauwkeurig vlakslijpen.

Dit mechanische gereedschap overbrugt de kloof tussen ruwe vormgeving en fijne afwerking. Er wordt gebruik gemaakt van gespecialiseerde messen om ruwe, zuivere of turbo-sneden te realiseren, afhankelijk van de projectbehoeften.

De mogelijkheid om messen snel te verwisselen maakt het tot een essentieel hulpmiddel voor aanpassingen ter plaatse waarbij draagbaarheid een prioriteit is.

📊 In één oogopslag:

- 📍Toepassingsgebied: Geavanceerd snijden

- 🏭 Kernsterkte: Precisiesnijden op locatie

- 🌍 Belangrijkste markten: Globaal

Waarom we ervoor kozen:

| ✅ De overwinningen | ⚠️ Afwegingen |

|---|---|

|

|

Professionele natzaag

Natte zagen bieden de **schoonste, chipvrije randen** die mogelijk zijn voor high-end steenpaneelinstallaties.

Deze zagen gebruiken een continue waterstroom om stof uit de lucht te verwijderen en tegelijkertijd het diamantzaagblad koel te houden. Deze opstelling ondersteunt hoog volume zagen voor grote projecten zonder de steen te beschadigen.

Ze zijn de voorkeurskeuze voor het bereiken van strakke, professionele verbindingen op dik materiaal natuursteen platen waarbij precisie voorop staat.

📊 In één oogopslag:

- 📍Toepassingsgebied: Geavanceerd snijden

- 🏭 Kernsterkte: Spaanvrije precisiesneden

- 🌍 Belangrijkste markten: Globaal

Waarom we ervoor kozen:

| ✅ De overwinningen | ⚠️ Afwegingen |

|---|---|

|

|

Metselaarsniveau (geestniveau)

Deze tool zorgt voor **perfecte structurele uitlijning** over uitgestrekte gebieden stenen oppervlakken door te voorzien een duurzame, goed zichtbare referentie voor verticale en horizontale nauwkeurigheid.

Professioneel steenhouwers gebruiken deze zware niveaus om te onderhouden precision during the assembly of large wall surfaces. Most units measure four feet or longer, allowing the user to bridge multiple stones and detect subtle height variations that shorter tools might miss.

The rugged frames withstand frequent contact with abrasive stone materials and mortar. This durability makes it a fundamental requirement for achieving the tight tolerances and geometric continuity expected in high-end masonry projects.

📊 In één oogopslag:

- 📍 Application: Layout & Leveling

- 🏭 Primary Function: Structurele uitlijning

- 🌍 Availability: Globaal

Waarom we ervoor kozen:

| ✅ De overwinningen | ⚠️ Afwegingen |

|---|---|

|

|

Draagbare mortelmixer

This equipment **eliminates manual labor** and ensures every batch of mortar maintains the exact same strength and color for professional masonry.

Mechanische mengers automatiseren het voorbereidingsproces van het bindmiddel, wat van vitaal belang is voor de structurele integriteit van stenen metselwerk. Ze verwerken batches met grote volumes efficiënt, terwijl de chemische eigenschappen van het mengsel behouden blijven.

Deze machines verminderen de fysieke belasting van de bemanning en voorkomen de variaties in textuur die vaak voorkomen in handgemengde troggen. Een consistent mengsel zorgt voor een voorspelbare uithardingstijd en een sterkere hechting voor zware lijmsoorten natuursteen.

📊 In één oogopslag:

- 📍 Categorie: Materiaalbehandeling

- 🏭 Kernsterkte: Uniforme mortelconsistentie

- 🌍 Belangrijkste markten: Globaal

Waarom we ervoor kozen:

| ✅ De overwinningen | ⚠️ Afwegingen |

|---|---|

|

|

Wig en veren

Deze tool biedt een **betrouwbare methode voor schone, natuurlijke breuken** op dikke steen platen waar hamers tekortschieten.

Wedge and feathers consist of a center wedge and two shims that work together to split stone with minimal waste. Masons use this mechanical advantage to shape everything from granite blocks to landscape steps with high precision.

De process focuses pressure deep within the stone rather than on the surface, preventing unwanted spider cracks. It serves as the primary choice for onsite adjustments to oversized material when a natural aesthetic is required.

📊 In één oogopslag:

- 📍 Categorie: Specialized Splitting

- 🏭 Primary Function: Gecontroleerd steensplijten

- 🌍 Availability: Globaal

Waarom we ze hebben uitgekozen:

| ✅ De overwinningen | ⚠️ Afwegingen |

|---|---|

|

|

Beitels met hardmetalen punten

These tools offer **superior edge retention** and durability when trimming the hardest natural stones.

Carbide-tipped chisels serve as the industry standard for hand-finishing high-density materials like quartzite and granite. The inlaid carbide tip provides a hardened cutting surface that resists the rapid dulling typical of standard steel tools.

Masons use these tools for the final, critical phase of stone preparation where accuracy determines the quality of the joint. The reinforced construction handles repeated heavy impacts without compromising the integrity of the tool’s striking end.

📊 In één oogopslag:

- 📍 Application: Precision Shaping

- 🏭 Primary Function: Detailafwerking

- 🌍 Availability: Globaal

Waarom we ze hebben uitgekozen:

| ✅ De overwinningen | ⚠️ Afwegingen |

|---|---|

|

|

Commercial Verdict

Als je met ongeschikt gereedschap de bochten afsnijdt, loop je het risico dat 100% natuurlijk kwartsiet breekt en de 95% tintuniformiteit van onze steengroeve-inventaris van dezelfde batch wordt verpest. Door gebruik te maken van natzagen met een hoog koppel en troffels met vierkante uitsparingen van 1/2 inch zorgen ervoor dat de CNC-gefreesde randen perfect passen zonder zichtbare gaten. Deze professionele aanpak beschermt uw reputatie en beschermt projectmarges tegen dure herbewerkingen of aansprakelijkheidsclaims.

Elimineer giswerk door onze in elkaar grijpende Z-vormige panelen uit de eerste hand te testen bij uw volgende project. We raden u aan te beginnen met een proefbestelling van 300 vierkante meter om de structurele integriteit en naadloze afwerking van onze producten te verifiëren “Grote 10” inventaris. Neem contact op met ons verkoopteam om een volledige technische catalogus aan te vragen en de private label-opties voor uw regio te bespreken.

Fabrieksmatig gestapelde steen voor architectonische projecten

Waarom een hoogwaardige natzaag uw belangrijkste investering is?

Een professionele natte zaag beschermt uw projectmarges door een nauwkeurigheid van 100% te garanderen natuursteen installaties. Het behoudt de CNC-gefreesde randen van onze in elkaar grijpende panelen en zorgt tegelijkertijd voor een veilige, stofvrije werkplek die voldoet aan de moderne gezondheidsnormen.

Precisiesnijden voor zwaar kwartsiet en in elkaar grijpende panelen

Metselaars bereiken schone, chipvrije randen op dichte 6×24 natuurstenen panelen door gebruik te maken van een stabiel nat zaagplatform met hoog koppel. Deze zagen kunnen effectief omgaan met de verschillende diktes in onze voorraad, variërend van standaardpanelen van 1 cm tot 3,5 cm voor onze premium ruw gesneden series. Omdat we onze steen uit consistente steengroeveaders halen, vereist het behoud van die visuele uniformiteit sneden die de steen niet breken steen is natuurlijk korrel.

Het gebruik van watergekoelde diamantzaagbladen is essentieel voor het behoud van onze CNC-gefreesde randen op Z-Shape- en S-Shape-modellen. Deze precisie zorgt ervoor dat de “man-vrouw” Het verbindingssysteem sluit nauw aan en camoufleert verticale voegen voor een naadloze architectonische afwerking. Een goede koeling voorkomt ook thermische schokken in materialen zoals Alaska Grey-kwartsiet of California Gold-leisteen, waardoor materiaalverspilling tijdens complexe hoekaanpassingen en overgangen aanzienlijk wordt verminderd.

Silicastofonderdrukking en veiligheidsnormen op locatie

Natte snijsystemen elimineren tot 85% van het silicastof in de lucht, waardoor uw team voldoet aan de veiligheids- en gezondheidsvoorschriften op de werkplek. Dit is een cruciale factor voor aannemers die de aansprakelijkheid willen verminderen en een professionele omgeving willen behouden. In hoogwaardige wooninterieurs beschermt de onderdrukking van stof de bestaande afwerkingen en houdt de werkruimte schoon, wat de kwaliteit van onze hoogwaardige natuurlijke materialen weerspiegelt.

Naast de veiligheid houdt de continue waterstroom het steenoppervlak vrij van fijn sediment. Deze reinheid is nodig om te voorkomen dat stof de mortelverbinding op de achterkant van de panelen verstoort, waardoor een permanente hechting aan de ondergrond wordt gegarandeerd. Bovendien verlengt actieve koeling de levensduur van uw diamantzaagbladen. Dankzij deze lange levensduur kunnen onze partners een hoog productiviteitsniveau handhaven in grootschalige commerciële installaties, waardoor de projecttijdlijnen en winstbescherming intact blijven.

Diamantzaagbladen: welke korrel is het beste voor hard natuurlijk kwartsiet?

Voor professioneel kwartsietsnijden zijn de zachtheid van de binding en de segmenthoogte belangrijker dan de traditionele korrelgrootte. Wij raden diamantzaagbladen met zachte binding aan met een segmenthoogte van 15 mm tot 20 mm om een hoog silicagehalte aan te kunnen, terwijl de schone, chipvrije randen behouden blijven die nodig zijn voor naadloos in elkaar grijpende installaties.

Zachtheid en segmenthoogte binden boven traditionele korrel

Het selecteren van diamantzaagbladen met zachte binding blijkt effectiever dan alleen focussen op de korrelgrootte bij het hanteren van de extreme dichtheid van natuurlijk kwartsiet. We ontdekken dat een zachte matrix in combinatie met hoogwaardige diamanten ervoor zorgt dat het mes consistent nieuwe snijoppervlakken blootlegt. Voor de meeste commerciële installaties biedt een segmenthoogte van 15 mm de optimale balans tussen zaagsnelheid en duurzaamheid, vooral voor harde materialen zoals onze Glacier White- of Arctic Golden-kwartsietserie.

Vermijd harde bladen, omdat deze vaak glazig worden en niet meer snijden als ze te maken krijgen met het hoge silicagehalte dat inherent is aan onze natuursteen. We leggen de nadruk op het gebruik van zaagbladen met een hoge diamantconcentratie om een stabiel koppel te behouden en te voorkomen dat het gereedschap gaat ronddwalen tijdens diepe sneden. Deze stabiliteit is essentieel voor het behoud van de 95% kleuruniformiteit en structurele integriteit van onze steengroevematerialen van dezelfde batch.

Bladgeometrie voor CNC-precisie en in elkaar grijpende verbindingen

Utilizing split-segment blades helps reduce heat buildup and ensures clean, chip-free edges on Z-shape and S-shape panels. This geometry complements our CNC diamond-blade precision, allowing the male-female interlocking system to fit tightly for a professional architectural finish. By keeping the cutting edge sharp, you can effectively camouflage vertical joints and prevent the installation substrate from becoming visible.

For high-volume straight cutting where miter work is minimal, 20mm segments maximize the lifespan of the diamond matrix. This is particularly beneficial for large-scale projects using our standard 6″ x 24″ panels. Precision cutting at this stage reduces on-site labor and ensures that our matching L-corners synchronize perfectly with the wall transitions, maintaining the “Premium natuur” esthetiek van het project.

Hoe beïnvloeden de grootte van de troffel en de vorm van de kerf de morteldekking?

De afmetingen en geometrie van de troffelgroef bepalen de uiteindelijke morteldikte onder de steen. Voor zware architectonische panelen bieden troffels met vierkante uitsparingen het hoogste materiaalvolume, waardoor we de kritische dekking van 95% bereiken die vereist is voor buiteninstallaties en omgevingen met een hoge luchtvochtigheid, zoals de Golfregio.

Kiezen tussen vierkante, U- en V-vormige vormen

Troffels met vierkante tanden zorgen voor het hoogste mortelvolume. Dit maakt ze tot de standaard voor het bevestigen van zware natuurleien en kwartsietpanelen die worden gebruikt in moderne architectonische projecten. De vierkante ruggen bieden voldoende materiaal om de opening tussen de ondergrond en de natuurlijke gespleten achterkant van de steen te overbruggen.

U-notched trowels create rounded ridges that collapse more easily during installation. But they deliver less total material than square-notched alternatives. V-notched trowels spread the least amount of thinset and we typically reserve those for small mosaics or lightweight vertical applications rather than heavy ledgestone.

To prevent bond loss and future claims, installers must achieve 80% coverage for interior dry areas. For exterior walls or high-humidity environments, we require 95% coverage to ensure the stone resists environmental stress and stays securely bonded to the structure.

Sizing Trowels for Standard 6×24 Ledgestone Panels

We recommend a 1/2″ x 1/2″ square-notched trowel for our standard 6″ x 24″ panelen. Deze maat is nodig om het gewicht van 30-40 kg/m² effectief te kunnen beheersen en een permanente hechting te garanderen. Omdat onze steen met ruwe textuur een dikte van 3,5 cm kan bereiken, helpen grotere inkepingen installateurs rekening te houden met natuurlijke oppervlaktevariaties en onregelmatigheden in de ondergrond.

Elk met back-boter panel is een verplichte stap voor professionele B2B-installaties. Door een dunne laag mortel op de achterkant van het paneel aan te brengen, zorgt de lijm ervoor dat de natuurlijke spleten en holtes worden opgevuld. Deze techniek, gecombineerd met de juiste lijmkamgrootte, creëert een vacuümachtige verbinding die het zware natuurlijke materiaal ondersteunt.

Het gebruik van een troffel van de verkeerde maat, vooral die met smalle voegen, verhindert vaak het goed instorten van de rug. Dit leidt tot holle plekken en mogelijke scheuren onder thermische spanning. Door het juiste gereedschap te selecteren, wordt de structurele integriteit van de muur gewaarborgd en worden de winstmarges van het project op de lange termijn beschermd.

De rol van laserwaterpassen bij het garanderen van perfecte horizontale continuïteit

Laserniveaus projecteren nauwkeurige referentielijnen die een consistente hoogte behouden over bouwruimtes, wat essentieel is voor het uitlijnen van modulair natuurlijk stenen panelen. Door een stabiel horizontaal referentiepunt vast te stellen, zorgen we ervoor dat in elkaar grijpende Z-vormige en S-vormige systemen nauw aansluiten, de ondergrond verbergen en lelijke getrapte gaten in grootschalige architecturale projecten voorkomen.

Setting the Primary Control Line for Modular Panel Alignment

Projecting a constant laser reference line establishes the precise starting point for the first course of our 6″ x 24″ panels. This ensures the weight of the natural stone remains balanced and centered throughout the installation. By starting with a perfectly level foundation, installers avoid cumulative errors that often compromise the visual integrity of gestapelde stenen muren.

Self-leveling mechanisms in modern laser units automatically compensate for floor slope or uneven terrain. This feature is particularly important when installing our Z-shape or S-shape interlocking systems, as it prevents the “stapte” uiterlijk veroorzaakt door kleine verticale afwijkingen. Wij bieden deze in elkaar grijpende ontwerpen specifiek aan om verbindingen te camoufleren, en een laserwaterpas is het meest effectieve hulpmiddel om dat beoogde naadloze uiterlijk te behouden.

Het gebruik van een laser zorgt ervoor dat de CNC-diamantbladranden van elk paneel strak tegen elkaar aan zitten. Onze fabriek maakt gebruik van precisiesnijtechnologie om ervoor te zorgen dat modulaire stukken in elkaar passen met een mannelijk-vrouwelijk verbindingssysteem. Wanneer de horizontale controlelijn behouden blijft, elimineren deze precisieranden zichtbare gaten, waardoor de hoogwaardige architectonische afwerking wordt geboden waar hoogwaardige commerciële projecten om vragen.

Synchroniseren van overgangen voor grote gevels en geprefabriceerde hoeken

Zeer nauwkeurige roterende lasers handhaven een tolerantie van ±0,06 inch op 30 meter afstand, wat essentieel is voor het behoud van de horizontale continuïteit op massieve commerciële gevels en externe bekledingsprojecten. Voor B2B-aannemers die grootschalige ontwikkelingen beheren, vermindert dit nauwkeurigheidsniveau het herwerk ter plaatse en zorgt het ervoor dat horizontale aderen en texturen over de gehele gebouwschil uitgelijnd zijn.

Dankzij gesynchroniseerde hoogtelijnen kunnen teams onze bijpassende L-vormige lijnen uitlijnen hoeken met vlakke panelen perfect. We prefabriceren deze hoeken van 90 graden om textuur- en kleursynchronisatie bij muurovergangen te garanderen. Door een laser te gebruiken om de hoekplaatsing te begeleiden, garanderen installateurs dat de omhullende afwerking er op elke hoek van de constructie natuurlijk en continu uitziet, in plaats van onsamenhangend.

Continuous beams provide a reliable guide for installers to verify the fit of male-female connections in the interlocking series. This verification step ensures the substrate remains fully concealed behind the natural stone, protecting the structural layers from UV exposure and humidity. This precision not only improves the aesthetic value but also contributes to the long-term durability and profit protection of the project.

Dust Management: OSHA Compliance for Silica Protection on Site

Ensuring site safety and regulatory compliance requires maintaining respirable crystalline silica levels below 50 micrograms per cubic meter. By implementing written exposure control plans and using integrated engineering controls like wet-cutting systems, masonry teams can protect installers while meeting strict OSHA 29 CFR 1926.1153 standards.

OSHA 29 CFR 1926.1153 Standards and Exposure Limits

Professionele installateurs moeten het niveau van inadembaar kristallijn silica onder de toelaatbare blootstellingslimiet (PEL) van 50 microgram per kubieke meter houden gedurende een werkdag van 8 uur. Om dit te bereiken moeten managementteams een schriftelijk blootstellingscontroleplan (ECP) ontwikkelen waarin specifieke taken worden beschreven, zoals het snijden van 100% natuurlijk kwartsiet of leisteen, samen met de technische maatregelen die worden gebruikt om stof te verminderen. Het aanstellen van een aangewezen competente persoon zorgt ervoor dat de ECP actief blijft en dat de bemanningen de juiste huishoudprocedures volgen om de ophoping van stof op de werkplek tot een minimum te beperken.

Praktische technische bedieningselementen voor nat en droog zagen

Technische maatregelen bieden de meest effectieve bescherming tegen deeltjes in de lucht tijdens het prepareren van stenen. Wij adviseren het gebruik van geïntegreerde watertoevoersystemen op natte zagen bij het trimmen van onze 6″ x 24″ standaardpanelen om te voorkomen dat silicadeeltjes in de lucht terechtkomen. Voor binnentoepassingen waar water beperkt is, moeten bemanningen gebruik maken van lokale uitlaatventilatie (LEV) met HEPA-gefilterde stofzuigers die rechtstreeks op slijpmachines of zagen zijn aangesloten. Het gebruik van perslucht voor het reinigen van stenen oppervlakken of werkgebieden is volgens de huidige veiligheidsnormen ten strengste verboden om de recirculatie van bezonken silicastof in de ademhalingszone te voorkomen.

Waarom zijn gespecialiseerde zuignappen nodig voor grote paneelsystemen?

Gespecialiseerde zuignappen zijn essentieel voor het beheersen van het gewicht en de structurele integriteit van grote stenen panelen, waarbij belastingen tot 55 kg/m² worden verdeeld over meerpuntssystemen om breuk te voorkomen en tegelijkertijd de delicate natuurlijke texturen van leisteen en kwartsiet te beschermen tegen mechanische schade.

Voorkomen van structurele spanning en oppervlaktekrassen

Zwaar natuurlijk stenen panelen vereisen nauwkeurige bediening, vooral onze modellen met ruw profiel die een gewicht van 55 kg/m² kunnen bereiken. Het gebruik van standaard mechanische haken of staalkabels concentreert vaak de spanning op de randen, wat leidt tot scheuren of afbrokkelen. Meerpuntszuigsystemen lossen dit op door de belasting gelijkmatig over het paneeloppervlak te verdelen, waardoor de structurele integriteit behouden blijft tijdens zowel transport als de eerste uitharding in het mortelbed.

Naast gewichtsbeheersing beschermen deze hulpmiddelen ook de esthetische waarde van de steen. Onze leisteen- en kwartsietpanelen hebben natuurlijke gespleten en gespleten texturen die gevoelig zijn voor slijtage door metalen gereedschappen. Gespecialiseerde zuignappen maken gebruik van zachte rubberen componenten die minimale contactspanning creëren, waardoor het nauwkeurig afgewerkte oppervlak vrij blijft van krassen of deuken die anders de architectonische waarde van het project zouden verminderen.

Verbetering van de uitlijningsprecisie voor in elkaar grijpende stenen panelen

Het bereiken van een naadloos uiterlijk met onze Z-vormige en S-vormige in elkaar grijpende panelen is afhankelijk van nauwe toleranties en perfecte uitlijning. Zuiggereedschappen geven installateurs de fijne controle die nodig is om de zuigmond in te schakelen “man-vrouw” verbindingssysteem nauwkeurig. Deze precisie zorgt ervoor dat de panelen verticale voegen effectief kunnen camoufleren en de installatiesubstraat verbergen, wat resulteert in een professionele, continue installatie stenen muur in plaats van een zichtbaar raster van individuele stukken.

Het handhaven van horizontale continuïteit over grote architecturale oppervlakken is moeilijk wanneer tegels met de hand worden verschoven, omdat handmatige beweging vaak het mortelbed verstoort. Deze zuigsystemen maken kleine aanpassingen mogelijk zonder de hechting tussen de zuigsystemen in gevaar te brengen steen en de muur. Door deze tools naast laserwaterpassen te gebruiken, zorgen installateurs ervoor dat elke baan waterpas blijft en dat de CNC-diamantbladranden precies in elkaar passen zoals ontworpen.

Veelgestelde vragen

Hoe gestapelde steen zagen zonder afbrokkelen of barsten?

Wij raden u aan een professionele natzaag met een diamantzaagblad met doorlopende rand te gebruiken. Water werkt als smeermiddel om wrijving en hitte te verminderen, waardoor het 100% natuurlijke kwartsiet of leisteen niet breekt. Voer het paneel langzaam door het blad om de nauwkeurig gesneden, in elkaar grijpende Z-vormige randen te beschermen en een naadloze architectonische afwerking te garanderen.

Welke maat troffel voor standaard 6×24 stenen panelen?

Een troffel met vierkante tanden van 1/2 inch is ideaal voor onze 6″ x 24″ panelen. Omdat onze standaardpanelen tot 12 lbs per vierkante voet wegen, biedt deze kerfgrootte de diepte die nodig is voor een veilig mortelbed. We raden ook aan om de achterkant van elk stuk te beboteren om volledige dekking en langdurige structurele integriteit van de muur te garanderen.

Kan ik een haakse slijper gebruiken in plaats van een natte zaag?

Voor kleine inkepingen in stopcontacten of gebogen uitsparingen kunt u een haakse slijper gebruiken, maar voor lange, rechte zaagsneden is een natte zaag nodig. Een natte zaag biedt de precisie die nodig is voor een professionele afwerking en onderdrukt effectief silicastof, waardoor uw team tijdens de installatie aan de veiligheidsvoorschriften kan blijven voldoen.

Hoe binnenvloeren beschermen tijdens natzagen?

We raden aan om de natte zaag buiten op te stellen om opspattend water en steenslag uit de binnenruimte te houden. Als snijden binnenshuis onvermijdelijk is, gebruik dan stevige plastic zeilen en beschermende vloerplanken om de ondergrond af te schermen. Gebruik altijd een druppellus op het netsnoer om te voorkomen dat er water in het stopcontact loopt.

Beste hulpmiddel voor het verwijderen van overtollige mortel van het stenen oppervlak?

Een nylonborstel met stijve haren en schoon water zijn de meest effectieve hulpmiddelen voor het reinigen van het stenen oppervlak. Omdat we onze richelsteen uit specifieke natuurlijke steengroevelagen betrekken, moeten draadborstels of agressieve zuren worden vermeden die de natuurlijke gespleten afwerking kunnen beschadigen. Door overtollige mortel weg te schrobben terwijl deze nog vochtig is, blijft de textuur onberispelijk.