Mastering seamless corner secrets is the only way to prevent thin veneer applications from looking amateur and eroding project value. Improperly handled outside edges reveal substrate gaps and raw panel profiles, leading to high warranty claims and increased labor costs for installers and wholesalers.

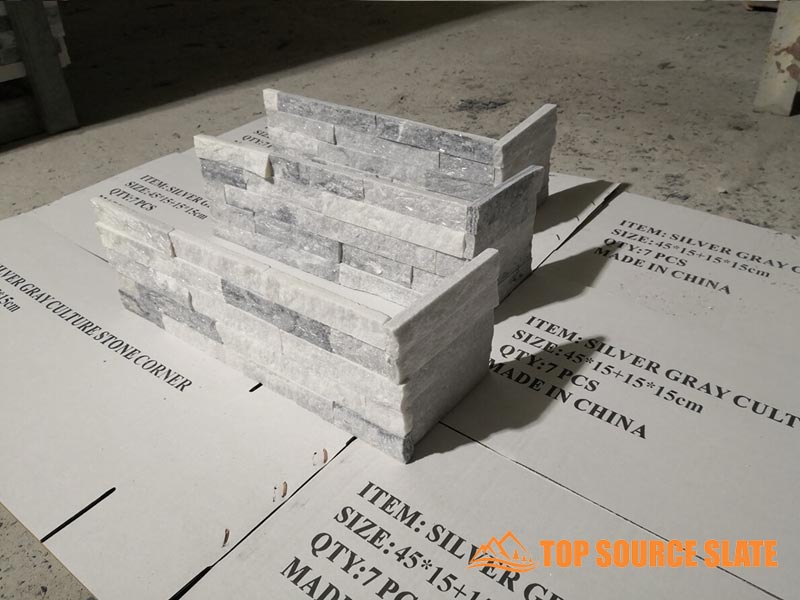

We solve this through factory-prefabricated L-corners featuring CNC diamond-blade precision and 95 percent hue uniformity. By sourcing components from the same quarry vein, these units maintain architectural integrity while reducing on-site installation time by 50 percent compared to manual miter cuts.

Why Corners Define the Quality of Your Entire Stone Project?

Corners reveal or hide the material’s nature. Proper execution creates a structural masonry illusion, directly increasing architectural value and distinguishing professional stone work from thin veneer aplicaciones.

Visual Authenticity and the Plane-Break Effect

Designers and inspectors focus on corners because they represent a natural break in visual uniformity. This change in plane is where the eye naturally lands. If the corner execution is sloppy, it reveals the thin profile of the veneer, signaling a surface-level application rather than structural masonry. Professional transitions hide the panel edges, ensuring the installation maintains the weight and presence of authentic stone.

Precision at these focal points determines the project’s long-term perceived value. A fireplace or facade that shows the substrate at the corner loses its luxury appeal immediately. By masking the seam where two planes meet, you create the appearance of solid, full-depth masonry. This detail separates an average contractor from a specialist.

Matching L-Corner Technology for Structural Synchronization

Field-cutting miters on-site often leads to uneven gaps and mismatched textures. Top Source Stone solves this through pre-fabricated 90-degree L-corners engineered for structural synchronization. We source these components from the same quarry vein as the flat panels to ensure 95% hue uniformity across the entire batch, preventing the patchy look common with third-party corner sourcing.

- Labor Efficiency: Pre-fabricated units reduce on-site installation time by 50% and eliminate the need for specialized miter-saw skills.

- Precisión CNC: Diamond-blade edges provide a tight “hombre-mujer” interlock that camouflages vertical joints and prevents the “efecto cremallera.”

- Dimensions: Matching corners available in 6″ x 24″ or 6″ x22″ formats to fit standard ledgestone series.

- Tecnología perfecta: The interlocking structure conceals the installation substrate and eliminates visible “pisó” gaps in the final facade.

Using factory-made corners protects the profit margins of wholesalers and dealers by reducing material waste and site errors. These units provide a wrap-around finish that mimics full-depth block, providing a professional result that stands up to close inspection in high-traffic commercial and residential environments.

The Pro Choice: Efficiency Benefits of Factory Pre-fabricated L-Corners

Factory L-corners reduce installation time by 50% and labor costs by 25%. CNC diamond-blade cutting ensures seamless texture synchronization and eliminates the ‘zipper effect’ common in manual site-cutting.

| Efficiency Metric | Factory Pre-fabricated L-Corners | Manual Site-Cutting |

|---|---|---|

| Installation Velocity | 50% Reduction in on-site hours | High (Requires individual miter cuts) |

| Labor Expense | Lowered by up to 25% | Premium (Requires master stone masons) |

| Desperdicio de materiales | 90% Reduction (Zero site scrap) | High (10-15% breakage/off-cut loss) |

| Precisión & Fit | CNC-Diamond Precision (90°) | Variable (Susceptible to human error) |

Accelerated Installation and Labor Cost Mitigation

Standard diagonal-cut methods on a job site consume excessive billable hours and demand high-level masonry expertise. Our pre-fabricated L-corners bypass this bottleneck by arriving as ready-to-mount units. These components reduce total installation time by 50% because crews spend their time setting stone rather than measuring and grinding angles.

Project developers also benefit from parallel construction workflows. We manufacture the corner units at the factory while your team prepares the site substrate. This overlapping schedule compresses the project timeline. By utilizing modular assembly, contractors lower total labor expenditures by 25% and minimize material waste by 90% compared to traditional masonry cutting practices.

Architectural Integrity via CNC Diamond-Blade Precision

Manual field cuts often result in the “efecto cremallera”—uneven joints and visible stepped gaps that reveal the stone as a veneer. We solve this by using CNC diamond-blade edges that guarantee strict 90-degree alignment. This industrial precision ensures the corner looks like a solid, full-bed stone block rather than two pieces meeting at a seam.

- Consistencia del lote: We source corner units from the same quarry vein as the flat panels to ensure 95% hue uniformity.

- Structural Stability: The factory joints are UV-stable and freeze-thaw resistant, meeting 2026 climate standards for extreme northern and coastal environments.

- Visual Continuity: Precision-cut fingers allow for a wrap-around texture synchronization that manual cuts cannot replicate.

- Tolerance Control: CNC automation maintains a 90-degree accuracy that prevents alignment drift across long vertical transitions.

Choosing pre-fabricated units protects the architectural intent of the design. These corners provide a seamless transition across wall planes, maintaining the luxury aesthetic expected by high-end commercial and residential clients.

Premium Stacked Stone for Architectural Needs

How to Execute Perfect Miter Cuts on Site (If Necessary)?

Use a 44.9-degree back-bevel and continuous-rim diamond blades to create tight, professional corners when pre-fabricated L-corners are not utilized for wall transitions.

While Top Source Stone provides matching L-shaped corners for every series to reduce on-site labor by 50%, certain architectural designs require custom field mitering. Achieving a factory-grade finish on paneles de piedra natural requires specific saw calibration and material handling to avoid revealing the veneer’s edge.

Angle Calibration and Back-Beveling Techniques

Precision at the corner determines whether the installation looks like authentic full-bed stone or a thin veneer. Most site errors occur because installers attempt a flat 45-degree cut on irregular wall surfaces.

- Back-Bevel Setting: Set the miter saw to 44.9 degrees. This slight adjustment ensures the show-face of the stone makes primary contact, resulting in a tighter visible seam while leaving a small internal gap for thin-set mortar.

- Sacrificial Fence: Secure a plywood fence to the saw bed. This provides a zero-clearance reference point for the blade path and supports the stone to prevent “reventones” at the end of the cut.

- Verification: Perform sample cuts on scrap pieces of the same thickness to verify squareness before processing full 6″ x24″ paneles.

Professional Field Cutting with Diamond-Blade Precision

Natural materials like slate and quartzite react differently to blade friction than ceramic or wood. Maintaining the integrity of the split-face texture during a cut is essential for a high-end architectural finish.

- Blade Type: Select continuous-rim diamond blades rather than segmented ones. The continuous rim prevents chipping on the natural cleft surface and mimics the CNC diamond-blade precision used in our factory.

- Material Selection: Pull pieces from the same crate to ensure same-batch quarry consistency. This synchronization of color and texture is critical at the corner transition where the eye naturally looks for breaks in the vein.

- The Bump Cut: Use the “bump cut” method for fine-tuning. Gently tap the stone against the spinning blade in the down position to shave off hair-thin amounts of material for a seamless fit.

To avoid these technical complexities, we recommend our project-ready L-corners. They provide a factory-finished 90-degree wrap that guarantees texture synchronization and eliminates the need for high-skill field cutting.

Uniones superpuestas: las “Junta a tope” Técnica para principiantes

Butt joints overlap stone panels to create 90-degree corners without complex miter cuts. This accessible technique provides a professional, woven finish for DIYers and beginner installers.

A butt joint is the most practical method for finishing stone corners when a wet saw or precision miter tool isn’t available. By overlapping the edge of one panel de piedra over the end of another, you create a structural 90-degree turn that protects the integrity of the wall while maintaining a clean aesthetic.

Executing the Alternating Corner Pattern

The goal of a successful butt joint is to hide raw edges and create a “woven” look that mimics traditional masonry. Following a specific mechanical sequence ensures the corner remains stable and visually balanced across the entire height of the wall.

- Positioning: Place the first panel so the end is perfectly flush with the edge of the substrate corner.

- Overlapping: Set the perpendicular panel so it overlaps the first, completely hiding the raw cut of the initial stone.

- Alternating: Switch the overlap direction on every row to create an interlocking appearance that mimics full-bed stone.

- Staggering: Offset the joints across the wall surface to prevent continuous vertical lines that weaken the installation.

Ensuring Seamless Gaps with CNC Diamond-Blade Edges

The precision of the stone itself determines how tight the final joint appears. While traditional hand-cut stone often leaves “daylight gaps,” factory-level engineering ensures these overlapping pieces sit flush for a high-end architectural finish.

- Bordes de precisión: We utilize Top Source Stone’s CNC diamond-blade edges to ensure the overlapping surfaces meet with zero visible gaps.

- Color Matching: Sourcing panels from the same quarry vein maintains 95% hue uniformity, making the transition between the two pieces invisible.

- Sealing: Apply high-strength epoxy resin at the contact point to block moisture penetration and reinforce the seam.

- Texture Alignment: Match the natural cleft face of the stone to the corner transition to create the illusion of a solid, heavy block.

By focusing on these technical details, installers can achieve a professional result that protects the project’s value without the labor overhead of custom on-site miter work.

Solving the Interior Corner Gap: Overlapping vs. Miter Options

Achieve professional interior corners by choosing between high-detail miter cuts or efficient overlapping joints, using CNC-precision panels to eliminate visible gaps and substrate exposure.

Comparing Miter Precision and Overlapping Joint Efficiency

Interior corners act as focal points that define the perceived value of a instalación de piedra. Contractors select jointing methods based on the stone’s texture and the required speed of the build. While mitering offers a traditional finished look, overlapping joints serve specific high-texture collections better.

- Miter Cuts: Installers angle the stone at 45 degrees to maintain a continuous texture flow across the corner, which is essential for linear or smooth-faced panels.

- Overlapping Butt Joints: This method involves placing one panel flush against the face of another. This works best for high-texture stone like our Rough Series, where natural thickness variations make miter alignment difficult.

- Blade Angle Offset: Setting saw blades to 44.9 degrees instead of exactly 45 degrees ensures the front edges meet tightly, hiding internal gaps and substrate.

Ensuring Seamless Fits with CNC Diamond-Blade Precision

Standard factory cuts often lead to the “efecto cremallera” or mismatched colors at the corner. Top Source Stone minimizes these on-site risks by utilizing automated manufacturing to stabilize panel dimensions before they reach the crate.

- CNC Diamond-Blade Cutting: Automated precision ensures 95% hue uniformity and perfectly straight edges, allowing for tight butt joints that do not require manual fillers.

- Same-Batch Quarry Sourcing: We pull materials from the same quarry vein per order to prevent color shifts at transitions, making corner joints effectively invisible.

- L-Corner Compatibility: Our factory-fabricated 90-degree corner units eliminate the need for manual site mitering, reducing installation labor by 50% for high-volume B2B projects.

How to Ensure Horizontal Alignment Across Corner Transitions?

Establish a laser-leveled baseline and use Piedras de origen superior CNC-cut L-corners. Working outward from corners ensures parallel stone courses and eliminates visible “pisó” gaps at transitions.

Maintaining linear consistency across a 90-degree turn requires more than just a steady eye. Any deviation at the corner amplifies as you move across the flat wall, leading to uneven courses that ruin the architectural aesthetic. Professional installers focus on the preparation phase to prevent these cumulative errors from occurring.

Establishing a Unified Baseline and Control Lines

The foundation of horizontal alignment starts at the lowest point of the installation. If the first row drifts even a few millimeters, the “efecto cremallera” will become glaringly obvious by the time you reach eye level. We recommend establishing a single horizontal reference that wraps around all wall faces before the first stone touches the substrate.

- Reference Setup: Set a 2026-standard laser level at the lowest point to create a consistent horizontal reference across every wall face.

- Vertical Monitoring: Mark digital control lines or snap chalk lines at 12-inch vertical intervals to keep course height consistent during the climb.

- Floor Compensation: Trim the bottom row of stones to fit the floor slope while keeping the top edge of that first row perfectly level.

- Dry-Fit Check: Dry-lay the first two courses around the corner to verify that the interlocking joints sit flush without vertical drift.

Utilizing CNC-Precision L-Corners for Texture Synchronization

Site-cut miters often struggle with texture gaps and color mismatches because the two pieces of stone weren’t originally joined. Top Source Stone solves this by providing factory-prefabricated L-corners. These units ensure that the la piedra natural character flows around the corner as if it were a solid, full-bed block.

- Visual Continuity: We use matching L-corners pre-fabricated to ensure color and texture synchronization at 90-degree transitions.

- Modular Fit: CNC diamond-blade edges provide clean lines that align perfectly with standard 6×24-inch flat panels.

- Seam Management: Alternate the ‘long-short’ staggered installation pattern with pre-made corners to break up vertical seams and maintain horizontal flow.

- Labor Efficiency: Seamless technology eliminates the need for complex miter calculations and hand-grinding, reducing on-site labor time by 50%.

Always install the corner pieces first. By setting the corner and working outward into the field, you ensure that any necessary adjustments happen in the center of the wall where they are less visible, rather than at the critical focal point of the corner itself.

Finishing the Edge: Polishing Raw Cuts to Match the Natural Face

Remove saw marks using 60–320 grit diamond pads, then use wire brushes and chisels to replicate the split-face texture for a seamless architectural transition.

Site-modified edges often expose the smooth, internal “heart” of the stone, which looks artificial compared to the factory-prepared face. When installers cut panels to fit specific dimensions or create custom miters, they must mechanically blend these raw cuts to maintain the aesthetic integrity of the Top Source Stone installation.

Graduated Sanding Sequences for Edge Smoothing

The primary goal of sanding is to eliminate the vertical grooves left by wet saw blades. A smooth transition prevents the “efecto cremallera” where the cut edge meets the natural cleft surface. Use the following progression for a professional finish:

- 60-Grit Diamond Pads: Grind down heavy grooves and align the plane of the cut with the adjacent stone panels.

- 120 to 220 Grit: Soften the sharp corners of the cut to mimic the slightly weathered look of piedra natural.

- 320-Grit Finishing: Create a tactile feel that matches our factory-prepared standards without over-polishing the stone into a reflective surface.

- Technique: Work in short, circular motions to prevent creating flat spots or dips in the material.

Replicating the Natural Cleft Texture on Exposed Cuts

Sanding provides the smoothness, but it lacks the rugged “Split-Face” character essential for a luxury look. Installers must manually distress the edge to mirror the CNC diamond-blade precision edges found on our standard Z-shape and L-corner units.

- Wire Brushing: Apply a heavy-duty wire brush to the sanded edge to pull out softer minerals and reveal the crystalline structure of Quartzite or Slate.

- Stone Chisel Work: Carefully chip the top corner of the cut at a shallow angle. This replicates the rugged depth and shadow profile of factory split-face panels.

- Color Matching: Seal the modified edge with a pH-neutral stone enhancer. This ensures the “Same-Batch Quarry” color consistency remains uniform across the entire wall surface.

Properly finished edges transform a standard veneer job into a high-end architectural feature. By following these mechanical steps, dealers and installers can guarantee a corner that looks like solid, hand-hewn stone rather than a thin panel product.

Preguntas frecuentes

Can I achieve professional corners without a traditional miter box?

Yes. Installers can use a bevel and fine-toothed handsaw or a custom cardboard template to guide the cut. Marking the wall directly with an angle iron ensures a precise fit, though you must smooth the edges with sandpaper afterward to remove jagged lines that create visible gaps.

What are the primary techniques for stone corner installation?

Projects typically utilize three methods: pre-fabricated L-corners, miter cutting, or the weaving technique. Top Source Stone provides factory-made 90-degree L-corners for every series to speed up installation and ensure color synchronization across the wall transition.

Do stacked stone panels require dedicated corner pieces?

Dedicated L-corners are essential for achieving a seamless, interlocking look. These components are manufactured to wrap around 90-degree angles, maintaining the Z-shape or S-shape modularity of the system while concealing the installation substrate and vertical joints.

How do I conceal raw cut edges on an outside corner?

The most effective method involves cutting the miter at 45.5 degrees rather than exactly 45. This slight over-cut ensures the outer faces meet tightly, burying the cut edge within the joint. If any raw edge remains visible, buffing it with a diamond polishing pad helps it match the natural split-face texture.

What is the most accurate way to cut a miter on thick natural stone?

Use a wet saw for a double-miter cut. Execute the first 45-degree cut, flip the stone piece, and make the opposite cut for the return. Cutting the return piece approximately 1/8 inch longer than the required depth helps hide thin-set mortar lines and creates a cleaner aesthetic.

Pensamientos finales

Precision corners differentiate a premium architectural project from a budget veneer application. Relying on manual field-cutting risks 15% material loss and costly “efecto cremallera” claims that erode your dealer reputation. Our CNC-engineered L-corners safeguard your profit by slashing labor time in half while ensuring 95% color consistency across the entire batch.

Secure your market position with our stacked stone panels, ready for dispatch within 15 days. We recommend a 300-square-meter trial order to verify our seamless interlocking technology and freeze-thaw durability firsthand. Email us for a detailed catalog or to arrange private label branding for your distribution network.