Precision corner miter techniques serve as the primary benchmark for stone installation quality, directly impacting project margins and long-term structural reliability. Improperly executed stone wraps lead to visible seams and crumbling joints that signal a low-budget installation, often resulting in expensive rework or client rejection during final walkthroughs. Achieving a seamless finish on fireplace pillars and external corners requires a rigorous approach to stone geometry, as even minor miscalculations in the cut angle can compromise the visual continuity of the entire architectural feature.

This guide establishes a technical standard operating procedure for stone wrapping, covering the mechanics of site-based 45-degree miter cuts and the use of pre-fabricated L-corners for a natural masonry appearance. We detail the specific workflows for managing non-90 degree custom angles, selecting appropriate diamond blades for dense quartzite, and the final honing methods used to eliminate visible cut lines. Following these procedures ensures that outside corners maintain the appearance of solid, hand-hewn stone while meeting the durability requirements of professional builds.

Why Bad Corners Reveal a Low-Budget Installation Quality?

Precision in stone cornering serves as the primary benchmark for distinguishing high-end architectural masonry from rushed, cost-cutting labor.

Corners serve as critical quality indicators in construction because they require precision and proper execution of finishing techniques. Uneven or poorly finished corners directly reveal shortcuts in labor and materials. When corners appear rounded, crooked, or inconsistent, it signals that the installation process was rushed. Because corner finishing is labor-intensive and cannot be easily concealed, it becomes a transparent indicator of whether a contractor invested the necessary time or took shortcuts to reduce costs.

Visible Seams and Exposed Raw Stone Cores

Low-budget installations often leave the internal, saw-cut edges of the stone visible to the eye, breaking the illusion of natural masonry. Cheap labor typically skips the honing or polishing of cut edges, leaving a dull, unnatural gray or white streak along the corner that contrasts sharply with the stone’s face.

- Precisie gesneden grootboekpanelen should meet tightly; visible gaps or heavy grout lines at the corner indicate a lack of specialized stone-cutting equipment.

- Geavanceerd projects prioritize a seamless transition where the stone’s face appears to wrap around the corner continuously.

- Exposed cores lack the UV stability and mineral texture of the natural cleft face, leading to faster weathering and a “manufactured” look.

Pattern Discontinuity and Visual Breaks

Poor craftsmanship fails to maintain the natural flow of stone textures around a 90-degree angle, making the installation look like a wallpaper application. Inexpensive installations often result in ‘stacked’ seams where the horizontal lines of the stone do not align from one face of the corner to the other. This break in the visual plane destroys the architectural “weight” that natural stone is supposed to provide.

- Experienced installers select specific pieces to mimic a solid boulder’s natural grain.

- Low-quality work uses random off-cuts at the edges, ignoring the color and texture matching required for a professional finish.

- Texture mismatching at the corner instantly signals to designers and high-end clients that the project prioritized speed over aesthetic integrity.

The Use of Field-Mitered Flats Instead of L-Corners

Budget-constrained contractors frequently attempt to create corners by hand-cutting flat panels at 45-degree angles on-site rather than investing in pre-fabricated L-shaped corner pieces. Field-mitered corners are prone to chipping and uneven gaps because manual wet saws lack the precision of factory CNC diamond-blade edges.

- Using factory-made L-shaped corners ensures the steen is natuurlijk face continues around the edge, providing the structural look of full-bed depth stone.

- Manual cutting on-site often fails to achieve the slight overcut (45.3 to 45.5 degrees) needed to ensure tight, gap-free joints.

- Relying on hand-cut corners significantly increases the risk of stone displacement in high-traffic commercial or residential areas.

Adhesive Bleeding and Structural Weakness

Corners are high-impact zones that require specialized bonding; poor installations often show messy adhesive residue or structural instability. Low-budget teams often over-apply standard thin-set, which can seep through corner gaps and permanently stain the natuursteen surface. This residue is difficult to remove without damaging the stone’s natural cleft.

- Proper installation uses high-strength epoxy resin specifically formulated for natural stone to prevent panels from pulling away at the joints.

- Inadequate support at the corner leads to ‘lippage,’ where one panel sits higher than the other, creating a sharp and dangerous edge.

- Standard thin-set lacks the lateral bond strength required to hold mitered edges together over long-term freeze-thaw cycles.

Miter Cutting on Site: Precision Tips for 45-Degree Natural Edges

Achieving professional-grade stone corners on-site requires a shift from standard carpentry logic to a precision fabrication mindset that accounts for natural stone density and irregular surface textures.

Essential Equipment for Precise Stone Fabrication

Clean 45-degree angles on natural ledger stone start with the right mechanical setup. We recommend using a high-quality wet saw with a continuous rim diamond blade, specifically a 15mm segment height if you are working with hard quartzite like our Alaska Gray or Sierra Blue models. The continuous rim prevents the micro-chipping common in slate or marble, while the 15mm height maintains edge stability through the entire length of a 24-inch panel.

Vibration serves as the primary enemy of a clean miter. Secure the panels using specialized stone jigs or heavy-duty clamps to eliminate movement during the pass. Using a digital angle gauge to verify the blade tilt ensures that the first cut matches the last, preventing the “drift” that often ruins bulk installations.

The 45.5-Degree Overcut Technique

Experienced installers avoid cutting at a perfect 45-degree angle. By setting the saw to 45.5 degrees, you ensure that the “true edge”—the visible front face of the stone—makes contact first. This creates a tight, seamless appearance on the exterior while leaving a microscopic interior cavity at the back of the joint.

| Specification | Standard Field Cut | Precision B2B Standard |

|---|---|---|

| Cutting Angle | Exact 45.0° (Risk of rear-collision) | 45.3° to 45.5° Overcut |

| Blade Selection | Standard Segmented Diamond | 15mm Split-Segment or Continuous |

| Joint Bonding | Silicone or Standard Caulk | Color-Matched Knife-Grade Epoxy |

| Cooling Method | Intermittent Water Spray | Constant High-Flow Water Lubrication |

This interior cavity provides the necessary space for high-strength epoxy resin. Without this relief angle, the adhesive can force the panels apart during the curing process, creating a visible “stapte” gap. By focusing the pressure on the sharp front edge, the joint remains structurally bonded and visually unified.

Managing Irregular Stone Thickness and Textures

Natuurstenen panelen like our “Rough Series” vary in depth, which complicates miter alignment. Always mark your cut lines on the back of the panel to protect the natural face from scratches. Before making the cut, align the thickest points of the two mating panels to ensure a continuous profile around the corner.

- Dry-fit all corner pieces before applying adhesive to check for “uitbarstingen” or thickness mismatches.

- Slow the saw feed rate significantly as the blade exits the stone to protect fragile edges on slate and marble.

- Maintain constant water flow to clear sediment; buildup can dull the blade and cause the stone to overheat.

Edge Finishing and Joint Reinforcement

The cut itself is only 90% of the work. Once the miter is cut, use a 200-grit diamond sanding pad to hone the raw edges. This removes micro-burrs and smooths the transition between the two panels, creating a “soft” corner that is less prone to chipping after installation.

For the final bond, use a color-matched, pH-neutral stone sealer on the cut edges before assembly. This prevents moisture from penetrating the raw stone core. We recommend a knife-grade epoxy for the actual joint; it provides a permanent, weather-resistant bond that mimics the factory-controlled quality of our pre-fabricated L-corners, ensuring the installation survives extreme freeze-thaw cycles without delamination.

Factory-Direct Pricing on Premium Ledger Panels

The Pre-fab Advantage: Why L-Corners Look More Like Natural Boulders

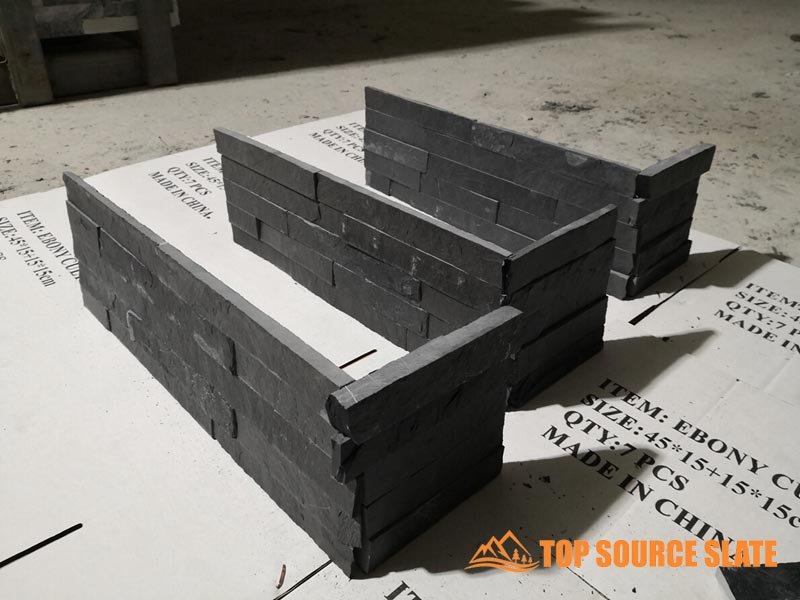

Pre-fabricated L-corners replace fragile manual miter joints with a monolithic stone appearance that maintains structural integrity and texture continuity across every wall transition.

Seamless Visual Continuity and Wrap-Around Texture

Manual miter joints often fail to hide the internal aggregate of the stone, creating a vertical line that screams “veneer.” Prefabricated L-corners solve this by providing a continuous stone face that physically wraps around the corner. This design hides the panel thickness and ensures the natural cleft and texture remain uninterrupted from one face to the next. We eliminate the “saw-cut” look entirely, as the corner piece mimics the geometry of a solid, heavy stone block found in traditional masonry.

- L-shaped pieces wrap around the corner to conceal the substrate and panel edges.

- Manufacturing processes preserve the natural split-face texture across the 90-degree transition.

- Seamless wrap-around faces prevent the exposure of internal stone cores or aggregates.

Factory-Precision 90-Degree Geometry

Achieving a perfect 90-degree angle on a job site with a handheld wet saw is nearly impossible over a large-scale project. We use automated infrared cutting tools to maintain exact dimensions, ensuring that every L-corner piece interlocks without gaps. This precision allows for predictable alignment across multi-story commercial facades or large residential fireplace pillars. To prevent corner separation over time, our factory-controlled bonding uses high-strength epoxy resins specifically formulated for the mineral composition of natural slate and quartzite.

| Functie | Manual Site-Cut Miter | Pre-fab L-Corner (CNC) |

|---|---|---|

| Angle Precision | Variable (Human Error) | Fixed 90° (Infrared Guided) |

| Installatiesnelheid | Slow (Manual Cutting) | Rapid (Ready to Install) |

| Structural Bond | Site-applied adhesive | Industrial-grade Epoxy Resin |

| Afvalfactor | High (Edge Crumbling) | Near Zero |

Consistency in Color and Material Grading

The most common aesthetic failure in stone installation is a color mismatch between the flat wall panels and the corner units. We mitigate this by sorting raw materials at the quarry level, ensuring that corner pieces come from the same mineral vein as the flat panels. This “Same-Batch Quarry Consistency” prevents the disjointed, patchwork appearance that occurs when contractors source materials separately. Every 2026 production batch undergoes a three-stage quality check to confirm hue uniformity remains at 95% or higher across the entire series.

- Quarry-vein matching ensures corner mineral patterns flow into the flat wall sections.

- A three-stage check confirms shading remains uniform across the 2026 product line.

- Unified batch sourcing prevents the “patchwork” look of mismatched stone.

Reduction of On-Site Waste and Labor Errors

Site-cutting fragile quartzite or slate into 45-degree miters inevitably leads to edge crumbling and high material waste. Ready-to-install L-corners lower the technical skill required to achieve a luxury finish while drastically shortening the construction timeline. The interlocking Z-shape system integrates directly with our corners, maintaining a grout-free aesthetic that looks like professional hand-laid masonry but installs in a fraction of the time.

- Contractors save labor hours by eliminating manual miter cuts on every course.

- Pre-fab units prevent breakage associated with cutting fragile stone types.

- The Z-shape interlocking system ensures a seamless, professional finish without visible vertical gaps.

How to Handle Non-90 Degree Angles in Custom Fireplace Shapes?

Precise custom angles require intentional over-cutting at 45.3 degrees and CNC-grade diamond blades to eliminate visible gaps in non-standard fireplace architecture.

Miter Cutting Techniques for Precise Custom Joints

Achieving tight seams on hexagonal or non-90 degree fireplace corners requires specific angular adjustments beyond standard 45-degree cuts. Most installers find that a perfect 45-degree cut leaves zero margin for substrate irregularities. We recommend setting your saw to a slightly aggressive angle of 45.3 to 46 degrees. This “back-cutting” technique ensures the outer stone points meet tightly while leaving a small internal void for high-strength epoxy resin.

Dry-fitting every stone panel is the only way to verify that custom angles align with the fireplace’s unique geometry. Since natuursteen varies in thickness and texture, you must check the face alignment before applying any adhesive. To maintain grain and texture continuity, cut the matching corner pieces from the same stone panel to wrap around the custom angle seamlessly.

| Parameter | Standard 90° Corner | Custom Non-90° Angle |

|---|---|---|

| Miter Cut Angle | 45.0° Standard | 45.3° to 45.5° (Back-cut) |

| Blade Selection | Continuous Rim Diamond | Split-Segment Diamond (15mm) |

| Bonding Agent | Polymer-modified Mortar | Color-matched Knife-grade Epoxy |

Essential Equipment for Stone Angle Adjustments

Professional-grade tools are necessary to maintain the integrity of natuursteen during complex angle fabrication. We utilize wet saws equipped with infrared guides to execute precise dimension cuts on ledger stone panels. These guides eliminate the guesswork when transitioning from a straight cut to a complex miter.

- Use ultra-fine-toothed diamond blades to minimize chipping on delicate materials like Alaska Gray or Midnight Slate during steep angle cuts.

- Apply blue painter’s tape along the cut line to clearly mark paths and protect the stone surface from vibration-induced micro-cracking.

- Maintain high water flow to manage heat and prevent the blade from glazing when cutting hard quartzite.

Modifying Ledger Panels for Non-Standard Fireplace Shapes

Adapting the Z-shape interlocking system for hexagonal or curved designs requires strategic panel modification. Our standard Z-shape panels are engineered for 90-degree transitions, so you must cut flat panels into custom-angled wedges for fireplaces that deviate from standard architecture. This allows the stone to “turn” the corner while keeping the interlocking mechanism functional.

Bond these custom mitered edges using high-strength epoxy resin formulated for 2026 stone standards to ensure permanent adhesion. On-site adjustment of the interlocking Z-tabs ensures a seamless appearance across custom-angled transitions, preventing the “stapte” gaps common in lower-quality installations.

Edge Finishing for Custom Angles

Manual refinement of raw stone edges is required when factory corners are modified for custom shapes. Polishing and honing the raw edges of mitered stone ensures they match the factory finish of our Flat or Pencil series panels. Use a progressive grit system, starting at 60 grit for material removal and finishing at 400 grit for a smooth, matte hone.

After the mechanical finish, apply a pH-neutral natuursteen sealer to the newly exposed cut faces. This prevents moisture penetration and staining while maintaining color consistency across the joint. For minor hairline gaps in complex joints, mix color-matched stone dust with resin to mask the seam and create a unified architectural look.

Finishing the Edge: Polishing and Honing the Raw Stone Cut

Technical refinement of the stone edge dictates the final visual grade and safety profile, bridging the gap between raw quarry extraction and architectural-grade cladding.

Precision Refinement with Infrared Cutting Technology

We utilize advanced infrared cutting equipment to establish precise, straight lines before any surface refinement begins. This high-precision phase eliminates structural irregularities in the natural slate or marble, ensuring panels interlock without the visible gaps typically found in lower-tier products. By achieving these dimensional standards in the factory, we reduce the need for aggressive site-side modifications that often lead to edge chipping or structural compromise.

- Advanced infrared tools create clean lines that allow Z-shape and S-shape panels to interlock seamlessly.

- Initial raw cuts prepare the stone for specific grit treatments by removing surface tension.

- Precision factory cutting preserves the integrity of the natuursteen edge, preventing crumbling during transit.

Progressive Grit Sequences for Honed and Polished Finishes

Achieving a specific architectural texture requires a systematic grit sequence. Honing involves a mechanical process using a grit range from 60 to 400 to remove surface scratches while creating a smooth, matte finish—a preferred choice for 2026 modern designs. For high-gloss requirements, our technicians continue the sequence beyond honing to produce a reflective surface that deepens the steen is natuurlijk color saturation.

Technicians monitor mechanical pressure and heat levels throughout this process to prevent micro-fracturing along the stone’s perimeter. This controlled material removal ensures that even hard quartzite maintains a crisp, professional edge without the “rounding” effect caused by amateur polishing techniques.

Maintaining Edge Integrity with pH-Neutral Solutions

Post-cut chemical management is vital for long-term stone health. We strictly use pH-neutral formulations during the polishing phase to prevent surface etching or color degradation. Using acid-based cleaners at this stage would ruin the natural mineral structure of materials like quartzite or marble, leading to premature fading or staining. Proper sealing after the final polish prevents moisture penetration, which is critical for high-traffic commercial applications.

- We avoid acid-based cleaners to maintain the natural hue and mineral stability of the stone.

- High-strength epoxy resin ensures the bond between the stone and the backing remains permanent after edge refinement.

- Final sealing stages protect the polished surface from oils and environmental debris.

Balancing Aesthetic Texture with 2026 Safety Standards

Current design trends influence edge texture as much as aesthetics. Satin and matte finishes have seen increased adoption because they provide superior slip resistance in vertical installations exposed to moisture or high humidity. In luxury lobbies, the honed edges of our Pencil Series create a sophisticated, linear flow that minimizes harsh light reflections, providing a softer visual experience than high-gloss alternatives.

Regular maintenance using only soft brushes and clean water keeps these refined edges free of debris. This simple care routine protects the stone’s surface integrity without the need for harsh chemicals that could strip the factory-applied finish or damage the interlocking joints.

Conclusie

Mastering fireplace corner transitions ensures a seamless wrap that reflects the quality of high-end masonry work. Integrating pre-fabricated L-corners or executing precision site cuts eliminates visible gaps and maintains the structural integrity of the natural stenen panelen. These technical details transform a standard installation into a durable architectural focal point that holds its aesthetic value for years.

Explore our inventory of natuurlijke gestapelde steen and matching corner solutions to simplify your next professional installation. Reach out to our team to request samples or to secure same-batch consistency for your upcoming large-scale projects.

Veelgestelde vragen

How to miter cut stacked stone without the edges crumbling?

To prevent crumbling, always use a professional-grade wet saw equipped with a fresh, continuous rim diamond blade. Ensure the stone is fully supported by the saw’s sliding table to minimize vibration. Apply a strip of painter’s tape over the cut line before starting to help hold the stone fibers together, and move the stone through the blade at a slow, consistent speed—never force it. Back-buttering the edge with a small amount of thin-set before cutting can also provide extra structural integrity for particularly brittle pieces.

Do I need corner pieces for my fireplace pillar?

While you can technically miter-cut flat pieces to form a corner, using pre-manufactured L-shaped corner pieces is highly recommended for a professional-grade installation. Corners are critical quality indicators; using dedicated corner pieces ensures a seamless, structural look that hides the thickness of the stone and avoids the “layered” appearance of a raw cut. This creates the illusion of full-depth stone blocks, providing a much higher aesthetic value and increasing the durability of the pillar edges.

How to hide the cut line on an outside corner?

The most effective way to hide a cut line is to use a color-matched stone epoxy or polyester resin mixed with a small amount of “stone dust” (crushed remnants of the same material). Apply this mixture into the seam of the miter. Once it begins to set, use a diamond hand-polishing pad to lightly buff the edge. This process blends the texture and color of the joint with the natural face of the stone, effectively erasing the visible transition line.

Best blade for mitering hard natural quartzite stone?

For hard natural quartzite, you must use a premium continuous rim diamond blade specifically engineered for hard stone or porcelain. Avoid segmented blades, as the gaps between segments cause “hammering” which will shatter the brittle quartzite. A thin-kerf blade is preferable because it removes less material and generates less heat, resulting in a much cleaner, chip-free mitered edge. Always use a high-volume water feed to keep the blade cool and clear away slurry.

How to fix a gap in a stone corner joint?

Naar fix gaps in stone corners, use a high-quality, color-matched sanded caulk or a stone-specific filler. For the best visual results, mix a clear stone epoxy with pigment or stone dust until the color matches the darkest veins of the stone. Press the filler into the gap, then use a small stiff brush or a piece of the stone itself to “stipple” the surface while it is still wet. This creates a natural texture that breaks up light reflections, making the gap repair indistinguishable from the surrounding masonry.